The subcontinent is making huge investments in state-of-the-art mobility. And rail plays a key role – Knorr-Bremse is a popular partner in the country. Even so, few people are aware that train services in India now run on almost fully electrified rails. The national rail industry aims to become climate-neutral by as soon as 2030.

“Demand for high-speed rail mobility is growing” – An interview with Frank Uder and Rajeev Gupta

As a member of the Board of Directors of Knorr-Bremse Asia Pacific (Holding) Limited, Frank Uder is responsible, among other areas, for the company’s activities in the Indian rail market. Rajeev Gupta serves as Director Sales & Marketing at Knorr-Bremse India Pvt. Ltd.

Mr. Uder, what did you think of India during your first business trip to the country?

Frank Uder: I thought it was a vast country that thoroughly deserves the sobriquet “subcontinent“ – gigantic, multifaceted, full of contrasts. What particularly struck me was its diversity: India’s constitution recognizes 22 official languages! What’s more, India has been impressively good at combining modern developments with traditional ways of life.

Mr. Gupta, you grew up in India. What was rail travel like when you were, for example, in your teens?

Rajeev Gupta: I still have clear memories of my time at college down south, in the 1990s. Back then, my family lived in New Delhi. Every time I made the journey, I would spend two days patiently sitting in a decidedly run-down train. Today, I spend less than a day. In general, the trip takes passengers around five hours, and they sit in a pleasantly air-conditioned compartment aboard the Vande Bharat Express, India’s intercity service. A lot has changed in the cities, too – the new metro networks are a particularly obvious example. Back in 2002, there were only two of them – one in New Delhi and one in Kolkata. By last year, there were 39 metro lines in operation in 17 cities. Between them, over the year, they carried more than three billion passengers in total. At the same time, the country is building new rail freight corridors – several thousand kilometers of track have been laid in recent years.

How are passengers in India reacting?

Rajeev Gupta: Traveling by train in India is relatively inexpensive. For most people, finding the cheapest way to travel from A to B is still the main priority. But as the middle class continues to grow, passengers’ expectations are changing. They’re increasingly interested in safety, punctuality and, in particular, comfort.

Diverse and rapidly growing – as a systems supplier, how do you tap into such a market?

Frank Uder: Above all, India’s rail market is still very price-sensitive. We can’t rely on one-size-fits-all solutions, which makes it essential to differentiate products, systems and services. We offer the most cost-competitive solutions for the specifications set out by our customers – but we also consult them whenever we see an opportunity to reduce costs by simplifying or innovating. It’s vital to tailor solutions to the marketplace, and we do so by referring to our global portfolio of solutions that already have proven track records in operation. As well as being cost-competitive, it’s essential that the solutions we provide to our Indian customers are technically reliable, especially in view of the harsh operating environment in India.

So for example …?

Frank Uder: … we offer technical solutions that have already proven their reliability in India. Our customers in India appreciate the fact that we reduce their operational risks while gradually upgrading systems based on field-proven equipment. To achieve this, we leverage experience gained from systems installed in comparable operating environments worldwide. As well as relying on us for economical, safe and reliable systems, our Indian customers are also turning to us for upgrades that will improve the safety of existing equipment – such as retrofitted automatic door systems with obstacle sensors, or locomotive brake control systems upgraded with India’s automated anti-collision system, KAVACH. But above all, it’s not just about finding the right solutions. The key to success in the Indian rail market is having a local manufacturing and servicing capability.

Why is that so important?

Rajeev Gupta: Traditionally, India has always prescribed a high level of localization as per the “Make in India” policy. To boost our economy, the government is promoting manufacturing in India across almost every sector. At present, manufacturers must build at least 50 percent of their products locally – and the quota for consumables can be as much as 100 percent …

Frank Uder: … which is why it’s so important that since 2013, we’ve been operating a major plant in Palwal, in the state of Haryana. The entire factory is based on Knorr-Bremse’s Group Production System (KPS). We’re able to manufacture all our products and systems in compliance with Indian rail industry standards – and that includes local engineering and development expertise. Just recently, we announced that we’re making another major investment in the Chennai region in southern India, enlarging our existing manufacturing and service footprint to accommodate the anticipated growth of this market by focusing on fully localized automated door systems in particular.

Freight corridors are coming online, metro networks are proliferating and the Vande Bharat Express represents a whole new approach to the country’s intercity traffic. What’s next on the list?

Rajeev Gupta: The next priority is high-speed travel, so we can offer a high-speed alternative to air travel over shorter domestic routes. The first step will be a 500-kilometer rail link between Mumbai and Ahmedabad. BEML Ltd, a major train manufacturer based in Bangalore, is building the first two prototype trains – and has just commissioned us to supply a whole range of system technologies for the new vehicles.

Metros on a growth curve

New metro lines are India’s answer to growing volumes of traffic in busy major cities. They take the pressure off the road network and create state-of-the-art links between city neighborhoods, improving people’s lives in sustainable ways. Knorr-Bremse is the leading supplier of braking, entrance and climate-control systems in India’s metro market.

Back in 1984, when India’s first metro line went into operation in Kolkata, the total length of metro track on the subcontinent amounted to just 3.4 kilometers. After a long pause, this was followed by the launch of the country’s second metro line in 2002. The new line in Delhi, India’s capital city, added 25 kilometers to the total. Since then, waiting periods have steadily fallen while track lengths have risen: In 2014, metro lines in five cities totaled 248 kilometers. By this year, the total track covered by 39 metro lines in 23 cities came to 1,000 kilometers. “By 2030, we’re expecting to see another 650 kilometers added to the total,” reports Shantanu Roy, Managing Director of Knorr-Bremse India. “By that time, Indian metro services will be collectively transporting around 4.5 billion passengers a year.”

Climate-control systems with optimized airflow

Since May 31, 2025, some of these services have also been operating in Indore’s Super Priority Corridor. As well as ordering braking systems from Knorr-Bremse, Madhya Pradesh Metro Rail Corporation Limited (MPMRCL), the operator of the new trains – all from Alstom’s Movia family – has also opted for Knorr- Bremse HVAC systems. More specifically, for a version with the company’s energy-saving Free Cooling function, CO₂ sensors, and a “smart” mode for regulating the supply of fresh air.

Delhi Metro Rail Corporation (DMRC) recently launched another major metro project involving Knorr-Bremse. The operator is building new metro lines for 52 six-car trains based on Alstom’s Metropolis platform. In particular, the new tracks will connect residential areas to the city center. Anyone traveling into the capital from further afield will find extensive parking facilities at the stations, enabling a seamless transition from car to metro.

Beneath the Hooghly River

India’s builders are not shying away from the technical challenges posed by the new lines. And Knorr-Bremse is the leading supplier of braking, entrance and climate-control systems to India’s metro market, providing solutions for almost every Indian metro network. The latest new line commissioned by Kolkata Metro, for example, runs under the Hooghly River in the north of the city. In Mumbai, kilometers of elevated track carry the new metro lines 4, 10 and 12 through the city. And in Delhi, the construction teams built two tunnels and a station in a densely populated neighborhood. At the same time, they relocated an extensive network of sewage pipes and overcame the challenges associated with high groundwater levels.

India enters the age of high-speed rail

At present, those traveling in a hurry from megacity Mumbai to bustling Ahmedabad prefer to fly. But soon, India’s first high-speed trains will offer an attractive alternative. Knorr-Bremse is equipping the prototypes with state-of-the-art system technologies.

According to airline schedules, flights from Mumbai to Ahmedabad generally take around one and a half hours. Realistically – assuming traffic conditions are good, and you use the toll road – the trip from Mumbai city center to the airport takes around 45 minutes; the same trip in Ahmedabad takes at least 30 minutes. Sensible travelers allow extra time – not to mention time spent waiting before their flight departs and, upon arrival in Ahmedabad, for their luggage to appear on the baggage carousel. Once high-speed trains start to cover the 508-kilometer distance at speeds of up to 280 km/h, the time difference between flying and traveling by train will simply fade away.

Knorr-Bremse technology for India

A high-speed alternative is exactly what the National High Speed Rail Corporation Ltd. (NHSRCL) has in mind. The Indian Railways subsidiary is responsible for the planning, funding, construction, maintenance and management of high-speed rail projects in India. In the summer, NHSRCL started by ordering two prototype trains from train manufacturer Bharat Earth Movers Limited (BEML) – and BEML in turn ordered a large number of system technologies from Knorr-Bremse, drawn from applications in projects around the world: braking and entrance systems, climate control and sanitary systems, as well as windshield wiper/wash systems.

Choosing Knorr-Bremse was no coincidence. First, because BEML and Knorr-Bremse have already successfully combined their expertise for numerous rail projects in India. And second, because Knorr-Bremse is the world’s leading supplier of systems for high-speed trains. With experience of exceedingly challenging applications around the world, Knorr-Bremse is the perfect partner for BEML and Indian Railways, delivering state-of-the-art high-speed rail technologies for the Indian market.

In progress: Studies for additional routes

The Mumbai-Ahmedabad corridor, which includes a 22-kilometer underwater tunnel, is already under construction. Planning and preparatory phases for other high-speed corridors are also in progress. India intends, for example, to build rail links between the capital Delhi and Ahmedabad, Amritsar and Varanasi. In addition, India’s Ministry of Railways has commissioned NHSRCL to draw up detailed project plans for high-speed links between Mumbai and Hyderabad via Pune, and between Mumbai and Nagpur.

Over the next two decades, Indian Railways aims to develop 7,000 kilometers of dedicated rail transit corridors across the country. These corridors are designed to support maximum speeds of 350 km/h, with a target operating speed of 320 km/h. The separation of high-speed passenger traffic from existing mixed-use track will improve efficiency and safety, forming the backbone of the country’s future rail infrastructure. The entire project will rely entirely on indigenous design, engineering and production – truly “Make in India.”

Local rays of sunshine

Working with Knorr-Bremse employees, Knorr-Bremse Global Care is creating new, localized prospects for people in need around the world. We take a closer look at Global Care activities in a Nepali camp in Vasant Vihar near Delhi and at an educational institution in Chinchwad near Pune.

In India, Nepalese immigrants comprise a large population of migrant workers. They often live with their families in informal or semi-permanent settlements. One such settlement, known as the “Nepali Camp”, is based in Vasant Vihar, not far from Delhi Airport. Living conditions in the camp are precarious. Here, more than 3,000 residents have limited access to communal sanitary facilities; their access to clean, safe water is also severely limited.

This has led to open defecation in the areas surrounding the camp. Women and children in particular have suffered under these unhygienic conditions, and from the associated health risks. Access to fresh, safe drinking water is severely restricted and the camp is reliant on the distribution of limited amounts of clean water delivered by non-government-controlled retailers. In 2024, Global Care worked with a national specialist NGO,

the Sulabh International Academy of Sanitation and Public Health, to restore a 44-seat toilet and sanitary complex. It includes a “Water ATM, a machine that dispenses clean filtered water in exchange for a small fee. The revenue helps to cover the costs of operating, maintaining and repairing the facility – a step toward self-management and better health. Solar panels provide the electricity required. The project includes health and hygiene courses for camp residents.

Training in digital basics and job-focused computer skills

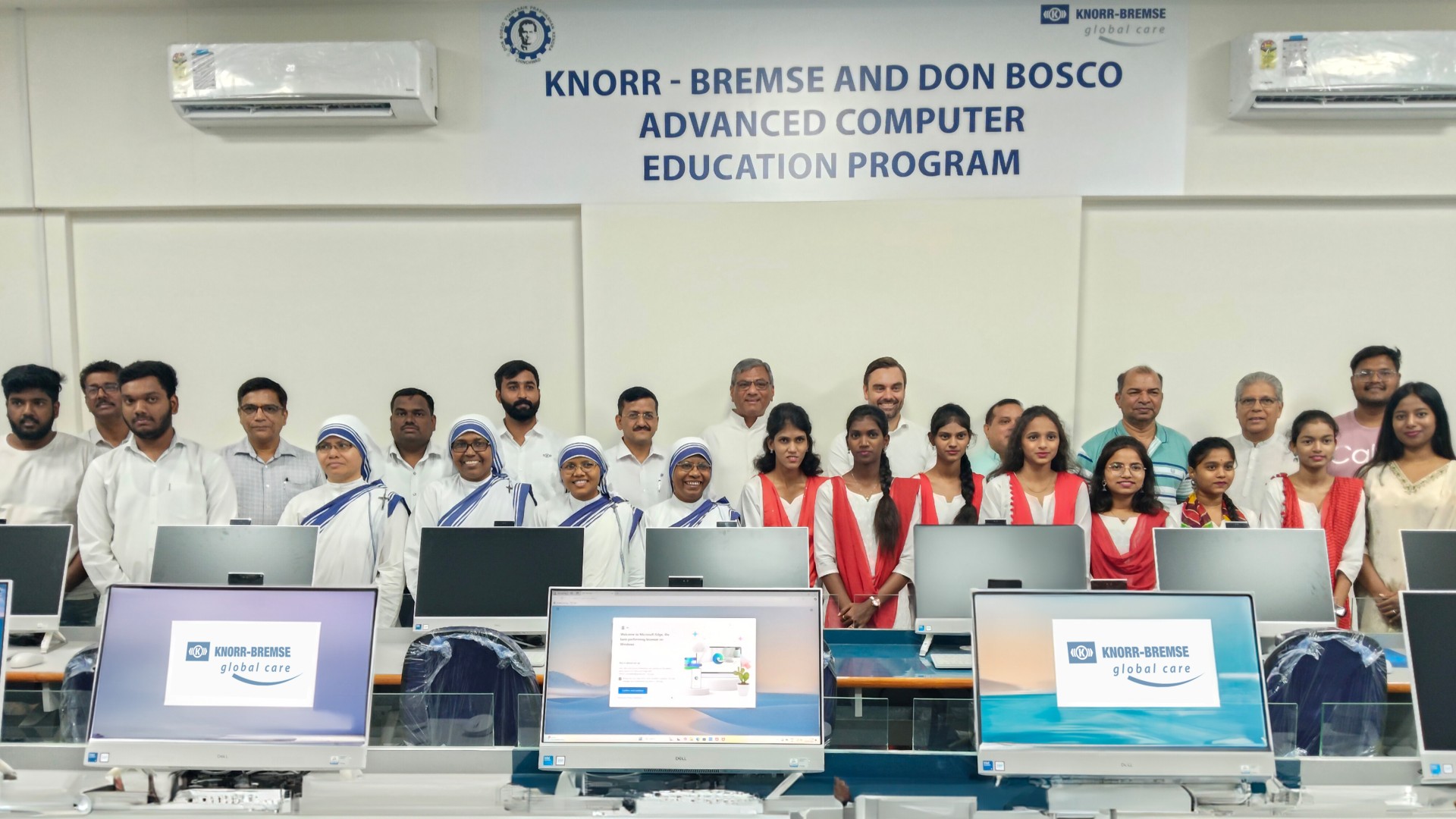

Moving on to Chinchwad near Pune, not far from the Knorr-Bremse Technology Center India, Global Care India funded the development and implementation of an Advanced Computer Education Program in partnership with NGO Don BoscoTraining College, with support from Knorr-Bremse Commercial Vehicle Systems. The courses on offer build the digital skills and computer know-how which teenagers and young adults from disadvantaged backgrounds will need to make the most of promising career opportunities in the future.

The training focuses on a healthy blend of theoretical knowledge and practical applications. Since the center was inaugurated in early 2025, nearly 30 trainees – comprising men and women in roughly equal numbers – have learned the basics of communicating by email, using MS-Office and, more recently, applying AI tools such as ChatGPT in courses lasting between three and six months.

Newly founded: Knorr-Bremse Global Care India

Regional integration is one of the fundamental principles driving Knorr-Bremse Global Care. In May, the association took an important step toward building an Indian presence by founding Knorr-Bremse Global Care India. The new entity now bundles the CSR activities of all three Knorr-Bremse business units in India (Rail Vehicle Systems, Commercial Vehicle Systems and the Technology Center). The Board of Directors is composed of senior executives from Knorr-Bremse’s global and Indian teams. The association already works through similar institutions in North America, and through a Hong Kong facility in the Asia-Pacific region.