Milestones of Knorr-Bremse's company history. 120 years of know-how and experience.

to

Success born of good ideas and perseverance

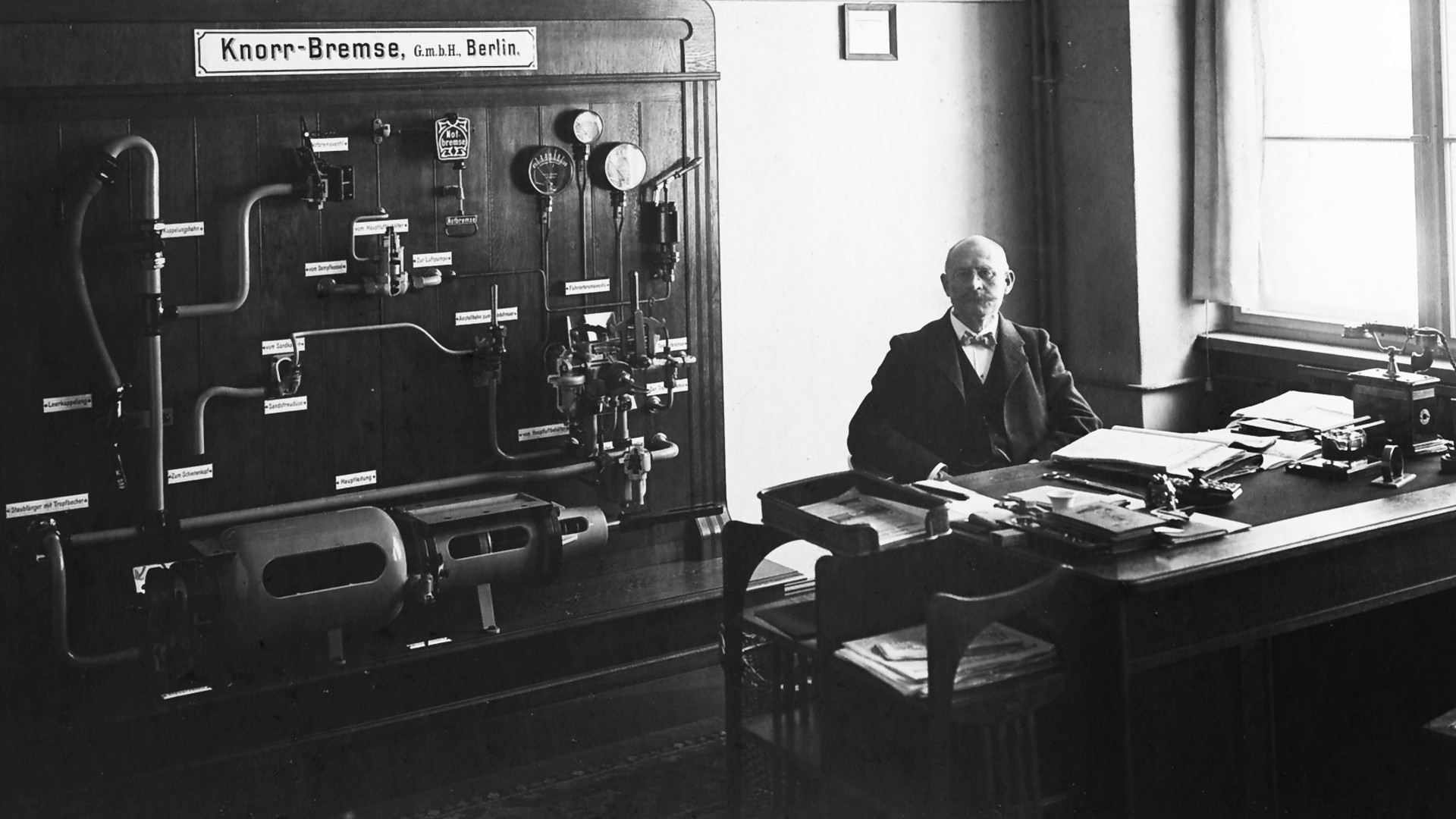

Georg Knorr establishes Knorr-Bremse GmbH in Berlin with the involvement of the machine tool manufacturer Loewe & Co. AG. As the owner of the company Carpenter & Schulze he has already been working for some twelve years on improving air brakes for trains. He thereby has the capital at his disposal to establish modern factory operations for production of the Knorr rapid release brake K1 and a development center for a new freight train brake. His "K1" brings passenger trains to a halt faster, more safely and above all without the customary juddering.

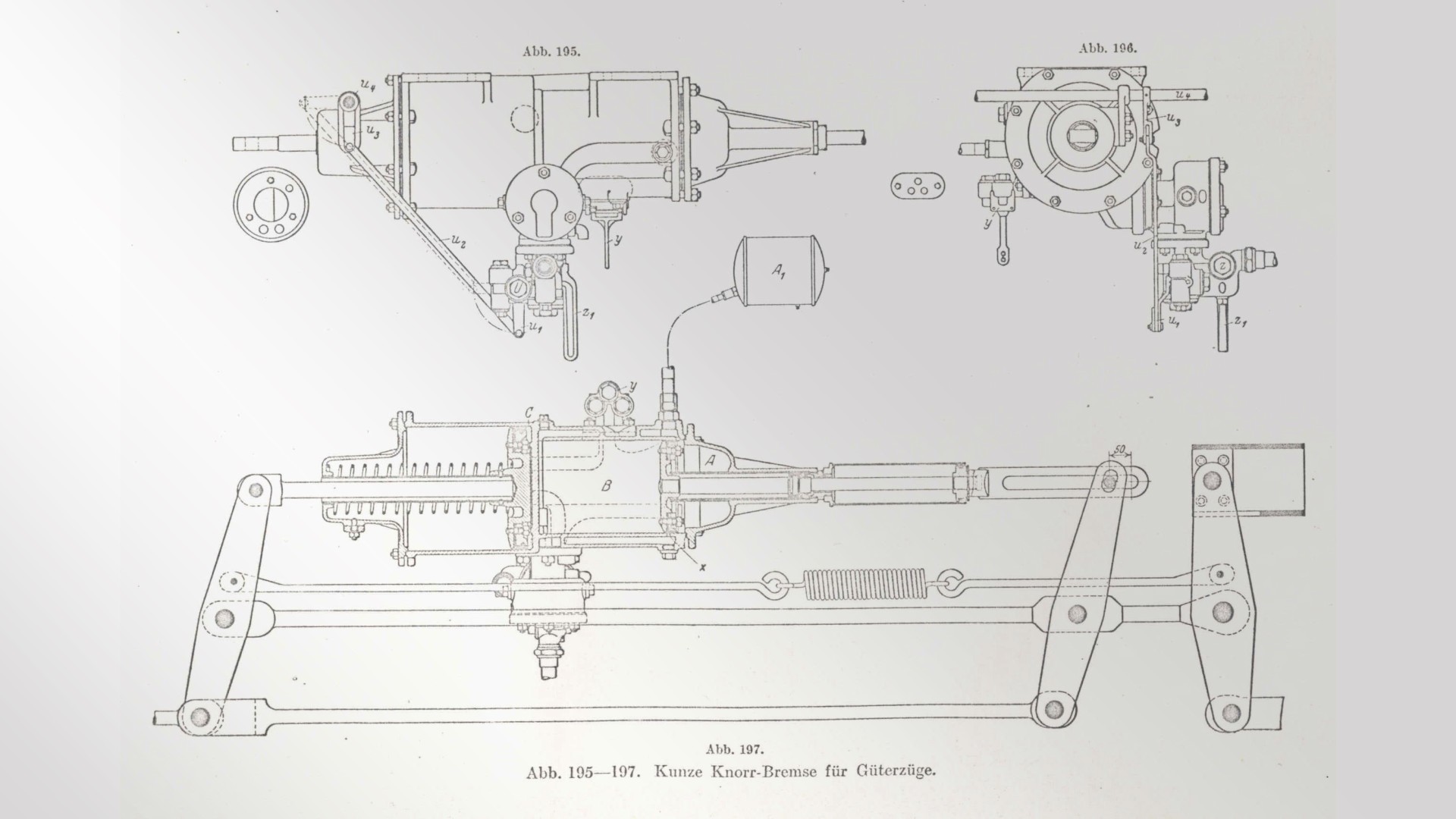

Breakthrough with freight train brake "Kunze-Knorr"

Inspired by an idea from Bruno Kunze, Head of the Brake Department of the Royal Central Railroad Office, Knorr develops a graduated release brake with low exhaustibility. The continuous Kunze-Knorr freight train brake avoids many accidents in trains on which brakemen, prompted by the train’s whistle, until then had to apply the brakes by means of a hand crank. As the only supplier of the new brakes for freight trains in Germany and other European countries, Knorr plays a crucial role in reducing accidents.

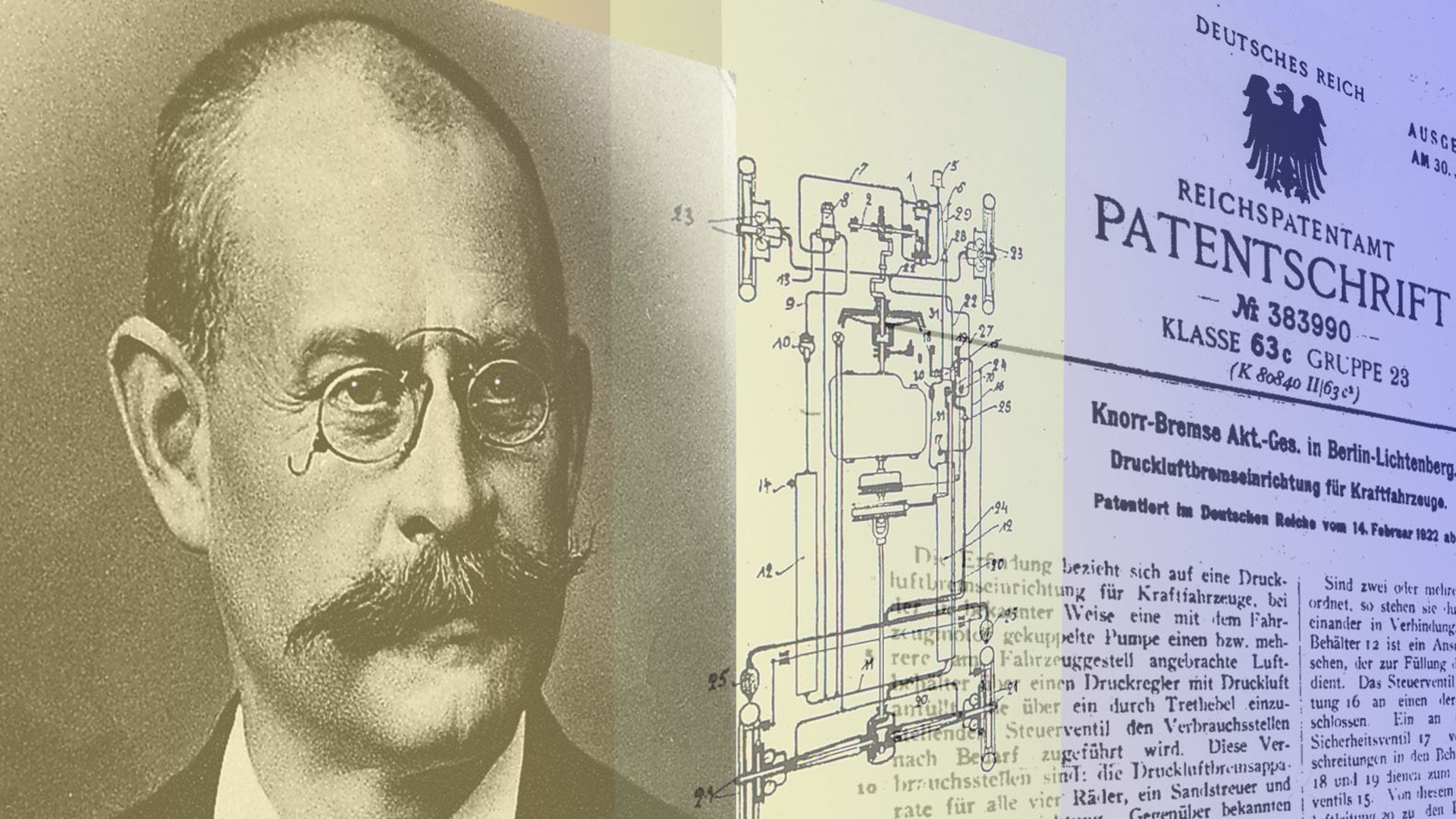

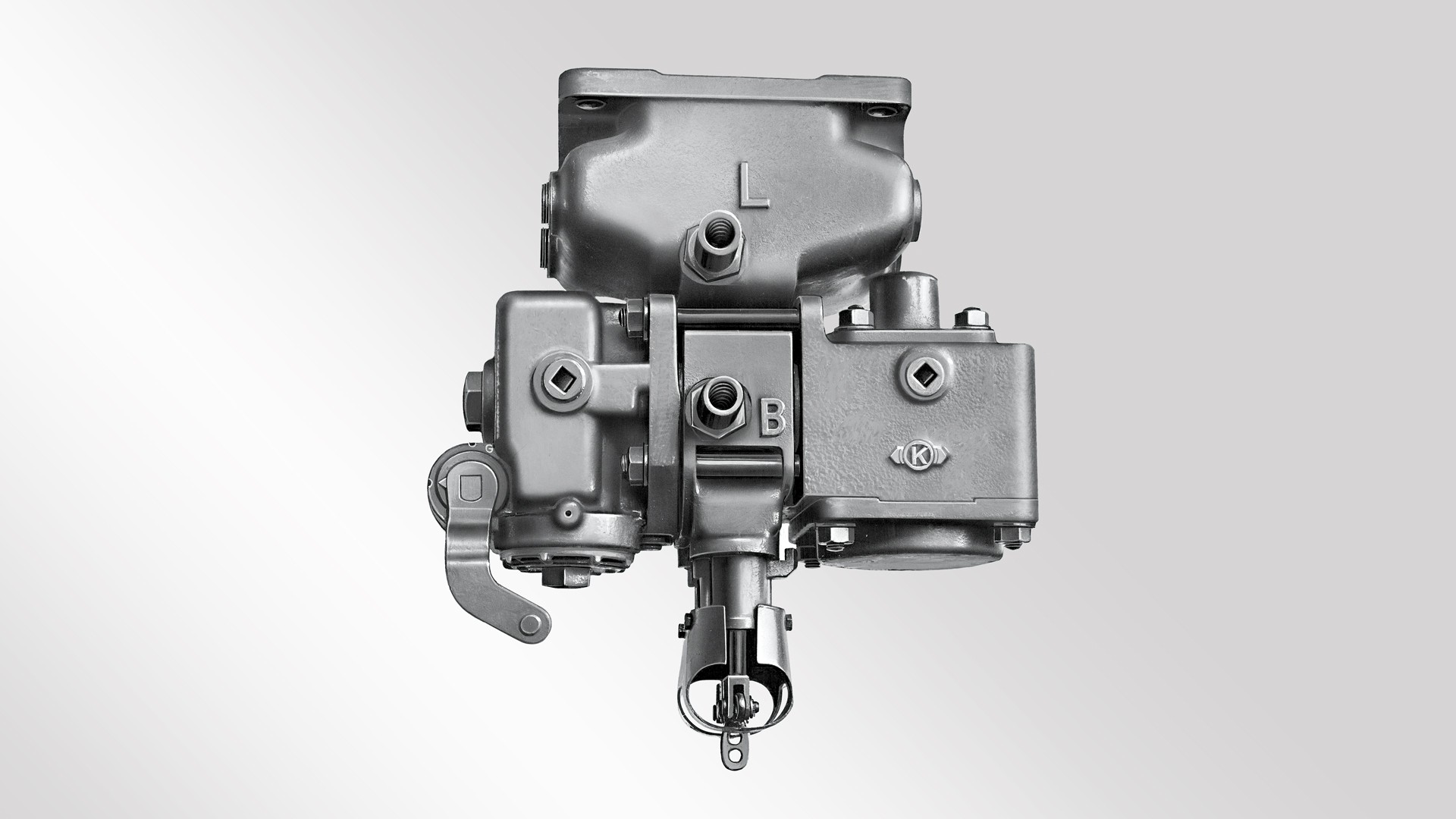

First patent for truck brakes

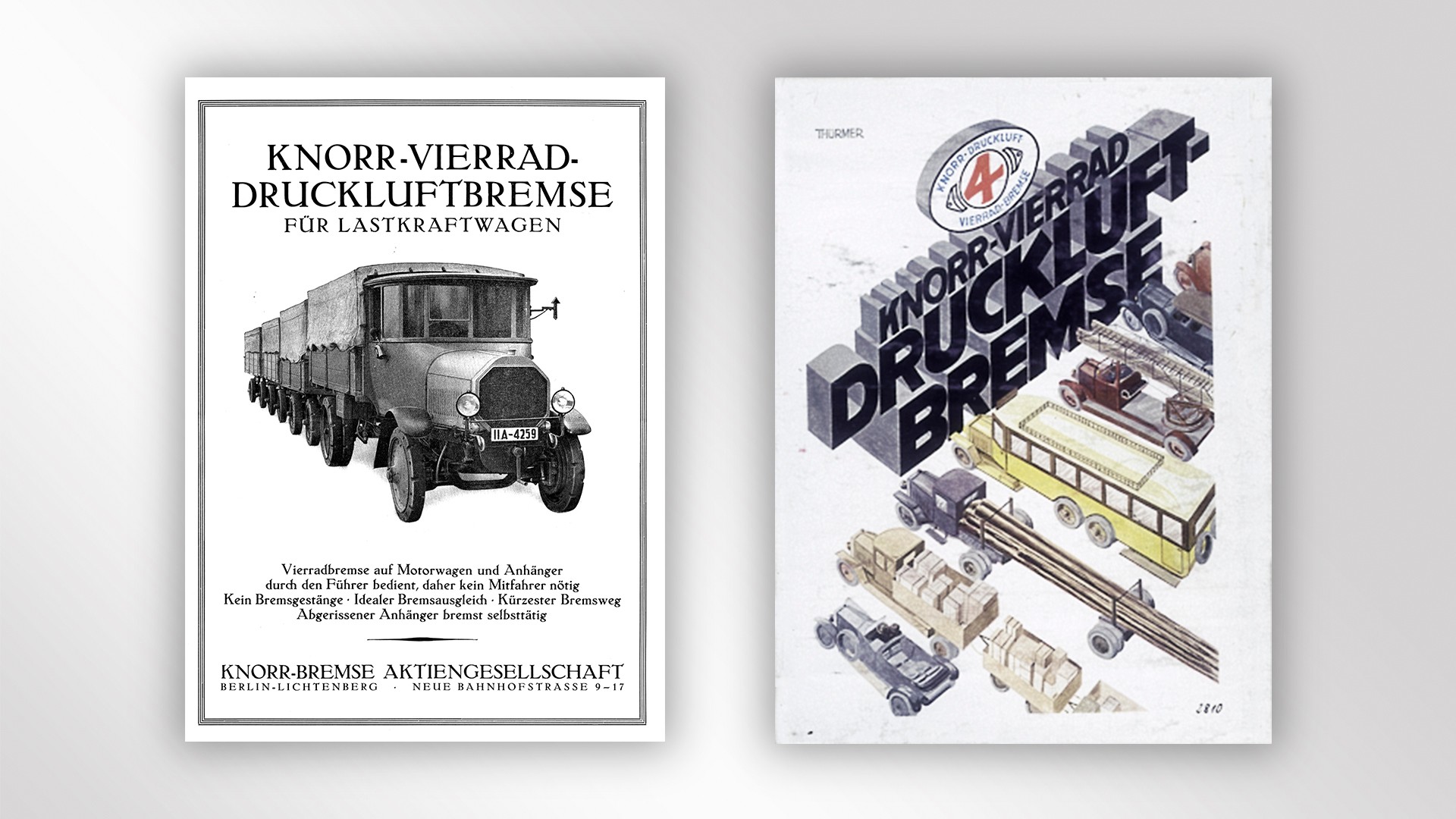

On 14 February 1922, patent application number 383 990 filed by Knorr-Bremse Aktiengesellschaft in Berlin-Lichtenberg paved the way for the triumphant success of the compressed air-operated wheel brake for commercial vehicles, which continues to this day. At the time of the filing, the rapid growth in road traffic called for a significantly better brake – to make travel faster and safer. With the Knorr four-wheel air brake, all four wheels of the truck can be braked directly – and simultaneously all four wheels of the trailer can be braked indirectly; braking distances were shortened.

First supplier of trucks with air brakes in Europe

The new Knorr four-wheel air brake really catches the eye in September 1923, when a Horch truck fully fitted with compressed air brakes on the tractor and trailer unit is unveiled for the first time at the Motor Show in Berlin’s Sportpalast. Knorr-Bremse then becomes the first company in Europe to equip trucks with four-wheel air brakes. From this point, the Knorr-Bremse brand is also a household name in road transport. In 1933, the magazine “Motor” reported from the Berlin Motor Show: “Knorr compressed air brakes have long since become a byword for the highest level of safety.” By the end of the 1930s, some 90% of all German trucks between 7 and 16 tonnes in weight are equipped with Knorr-Bremse systems.

The Hildebrand-Knorr brake (HiK) as new standard brake for trains

Wilhelm Hildebrand, technical director of Knorr-Bremse AG, designs the Hildebrand-Knorr-Bremse (HiK-Bremse), a further development of the Kunze-Knorr-Bremse. In 1931, the brake is introduced to the world. The new brake combines for the first time a high transmission speed of the brake signal, i.e. the speed at which a brake application penetrates to the end of the train, with near inexhaustibility. The brake was initially designed in two versions as a freight train brake and a passenger train brake. The express train brake followed in 1934. Even before the Kunze-Knorr brake had become widely used in Central Europe, a significantly improved system was already available in the form of the HiK brake. It becomes the standard in 17 countries; by 1955, 280,000 units are in operation.

to

Difficult times after the Second World War

Knorr-Bremse's main plant in Lichtenberg, located in the Soviet sector of Berlin, is completely dismantled and confiscated and expropriated for war reparations. Farsighted employees salvage construction documents, technical drawings, parts lists, and microfilms. The company resumes the development and production of braking equipment at the Südbremse plant in Munich. Munich becomes the new corporate headquarters in 1953.

Reconstruction with the Hildebrand-Knorr Brake (HiK)

The German Federal Railways, which succeeded the German Reichsbahn in 1949, produces around 18,000 new freight cars under the provisions of the Marshall Plan. These are equipped with HiK Brakes by Knorr-Bremse. All significant trains in Europe are now fitted with air brakes.

Worldwide success: the KE train brake with graduated release control valve

Following intensive development work by Dr. Ernst Möller and Dr. Friedrich Hildebrand, the son of Wilhelm Hildebrand, the Knorr Standard Brake (KE brake) is presented in 1953. The KE Brake can be used without restrictions together with older brake systems. Following approval by the European Union of Railways (UIC), the KE valve is now being used in over 40 countries, with almost 1.5 million units sold. The latest generation, KEf, is introduced in 2018.

New milestone for trucks: the automatic load-dependent braking system (ALB)

At the time of the German economic miracle, cars and trucks become means of mass transportation. Compared with the 1930s, traffic volumes have increased by a factor of six, and trucks are now bigger, heavier and faster. The frequency of accidents increases due to the dense traffic and badly maintained roads. The automatic load-dependent braking system (ALB) enhances safety by adapting the braking force to the axle load, i.e. the braking effect is made dependent on the load level. When the load is heavy, the braking effect is increased, and when the load is light, less braking is applied to minimize the risk of the wheels locking and increase the truck's driving stability.

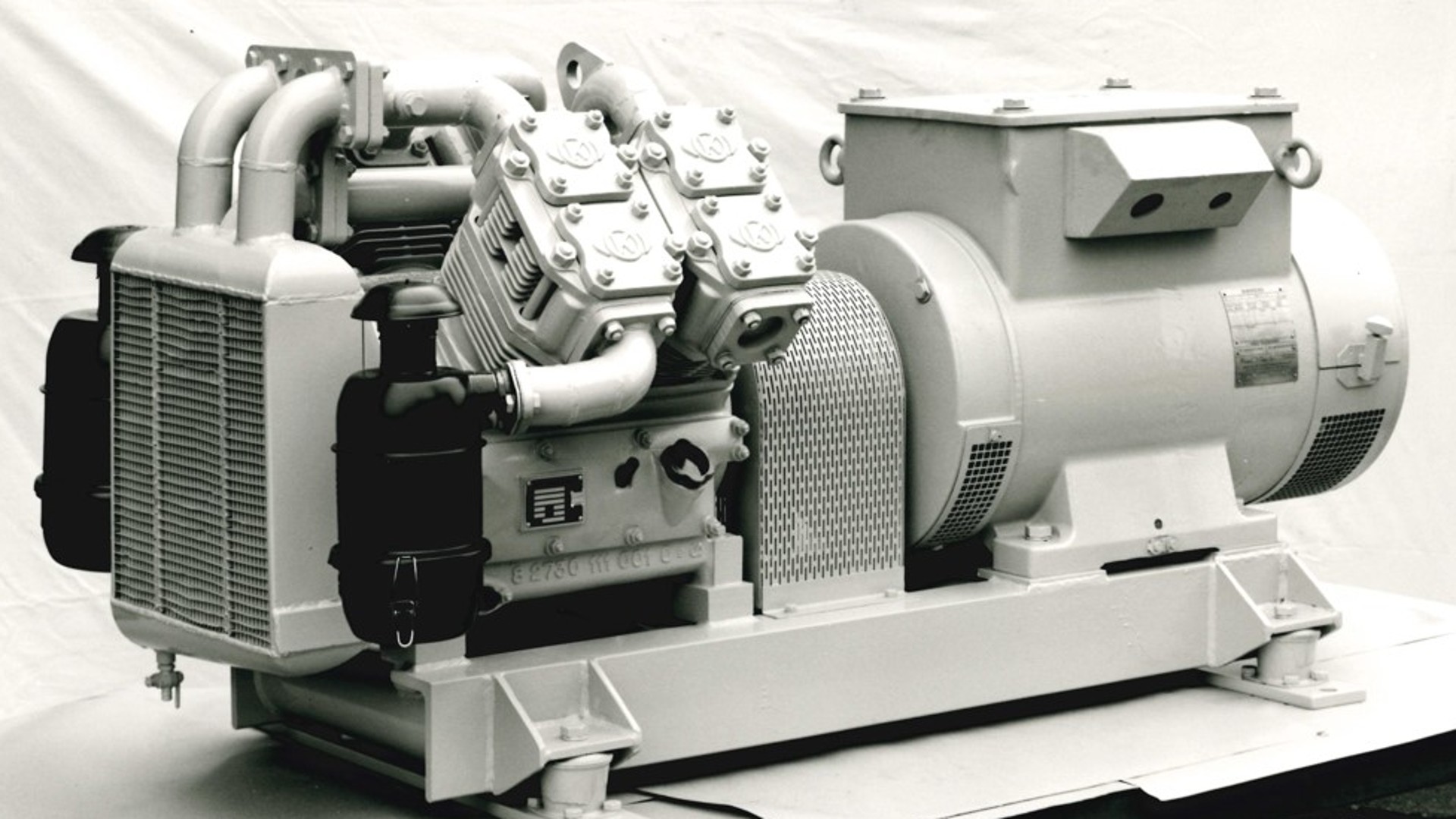

Air compressors from Knorr-Bremse - new applications for compressed air

Compressed air can do more than just brake: It is now also used for a range of further functions such as air suspension, level regulation, operating doors (e.g. on buses), or for pneumatic gearshifts. In the early 1960s, Knorr-Bremse offers a newly developed range of compressors.

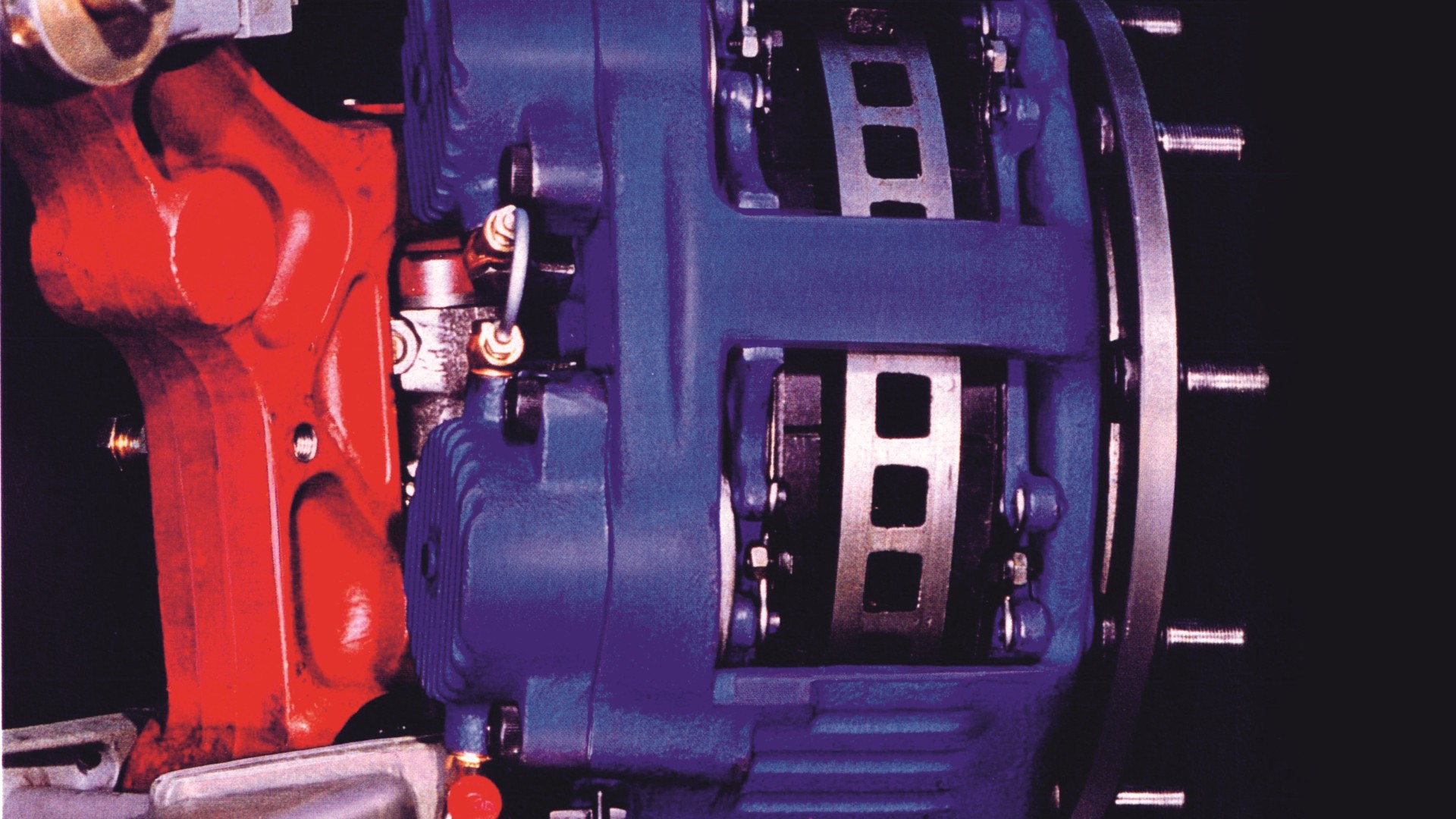

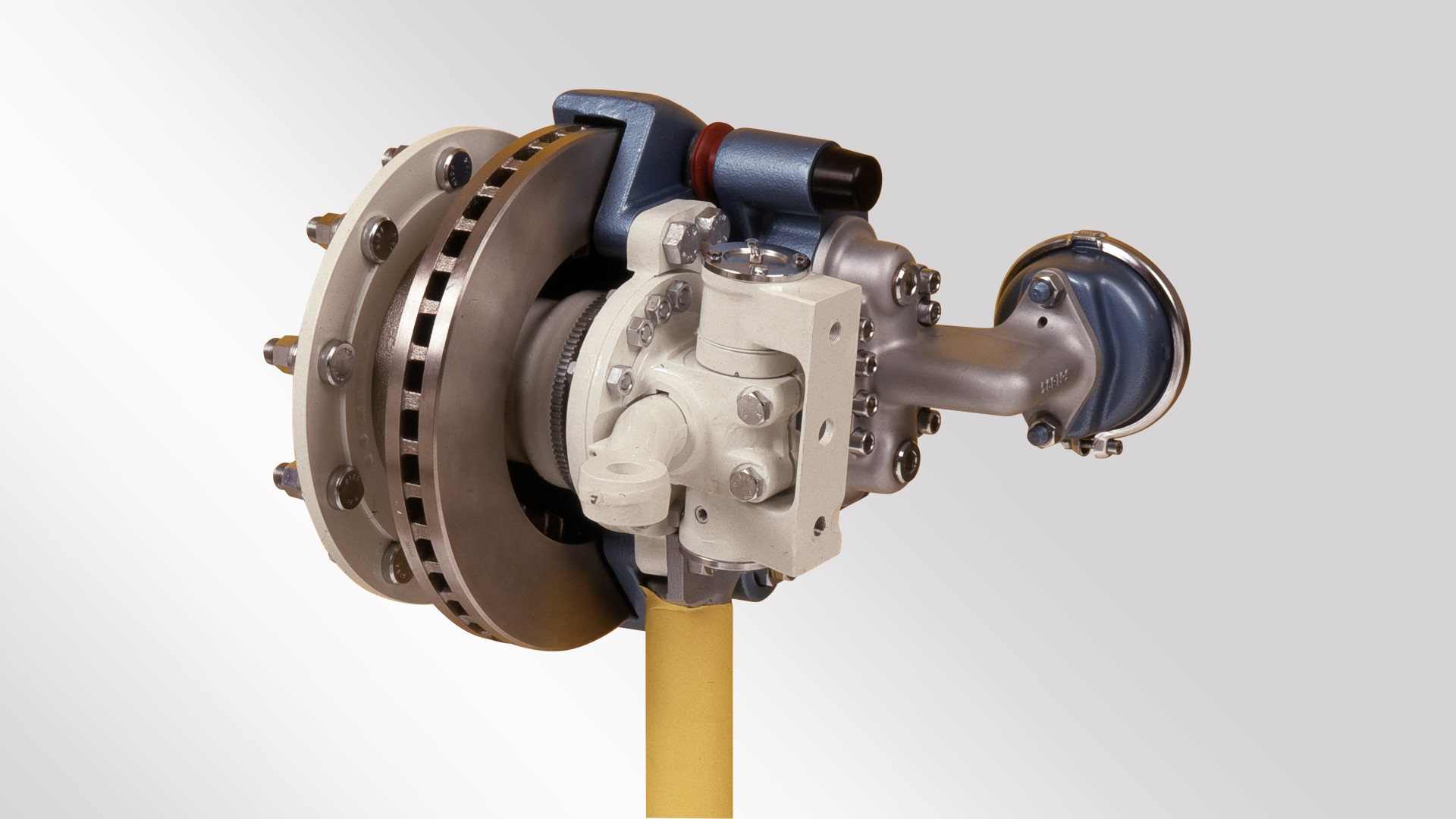

First series use of disc brakes in rail vehicles

The speed of rail transportation steadily increases with the advance of technology – and thus also the energy that is converted into heat during braking. Block brakes are no longer sufficient to withstand this increased thermal load. Knorr-Bremse offers disc brakes for trains with higher operating speeds.

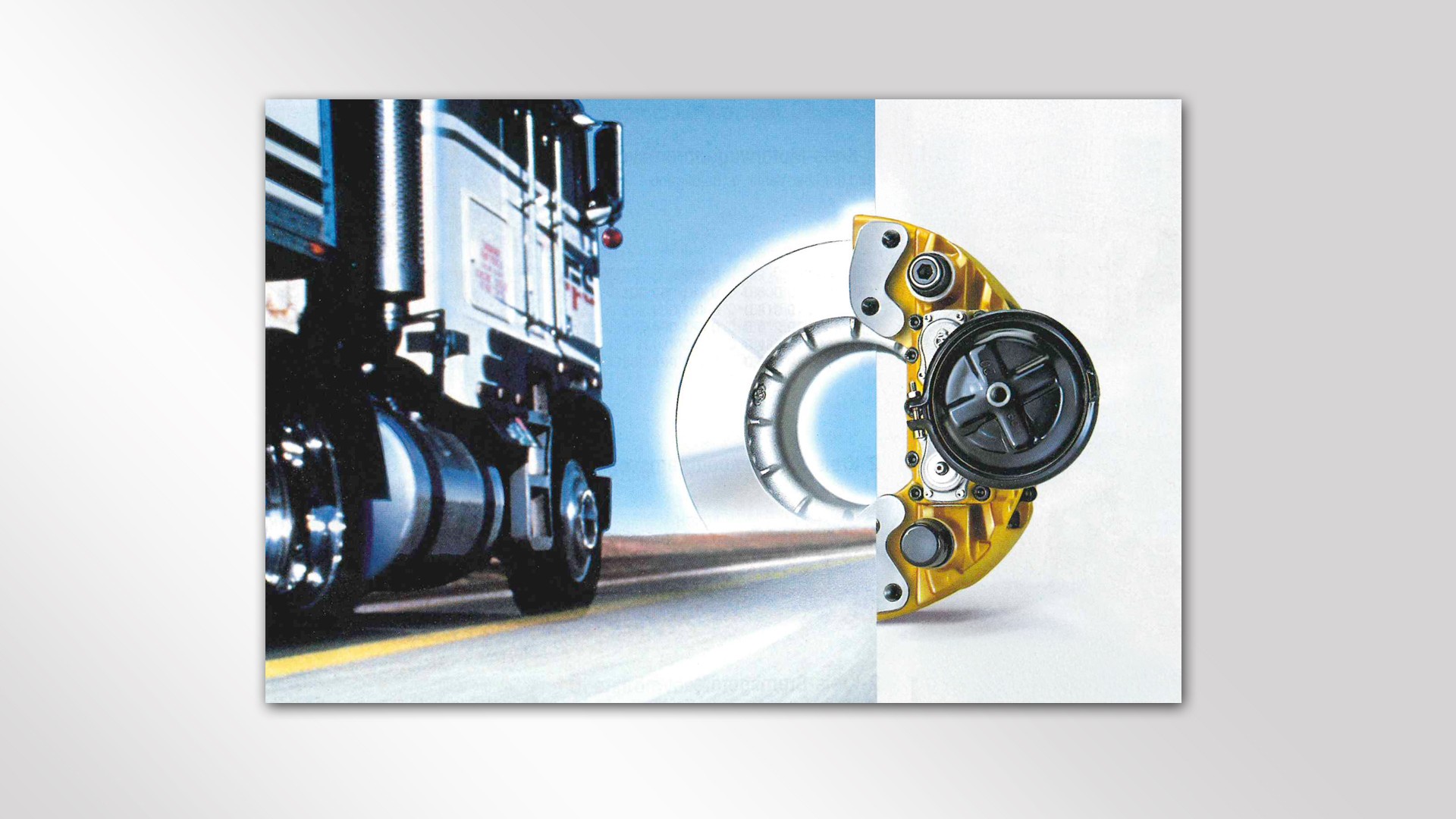

First disc brake for trucks

At the IAA trade fair in Frankfurt Knorr-Bremse presents the first disc brake for commercial vehicles: a hydraulically activated hinged-caliper disc brake. With this ventilated disc brake, Knorr-Bremse offers a technological alternative to the customary drum brake in commercial vehicles. However, this brake did not catch on in trucks due to its hydraulic actuation. It was therefore only used in certain niches, such as construction machinery or buses. 50,000 units are delivered to bus manufacturers by 1986.

Foundation of the US subsidiary Knorr Brake Corporation

»Tracks are back« – a popular slogan during the oil crisis in the USA. Knorr-Bremse benefits from this mood to gain a foothold in the American market and establishes the Knorr Brake Corporation. Initial orders lay the foundation for cooperation with local manufacturers in the modernization of the US railroads.

First electronic brake control system for urban rail vehicles

Knorr-Bremse equips urban rail vehicles with electronic brake control for the first time; this system integrates wheel slide protection and blending, requires fewer mechanical components, and attains shorter braking distances thanks to electric rather than pneumatic signals. Knorr-Bremse can thus considerably increase its global market share in urban transportation.

Anti-Lock Braking System (ABS) as standard in trucks for the first time

Complex problems have to be solved in the development of the anti-lock braking system (ABS) and acceleration skid control (ASR). Economically viable solutions are finally provided by microelectronics and digital technology. The first standard ABS is introduced by the development partner MAN in 1981.

First Brake Systems for high-speed trains

Knorr-Bremse provides the brakes for a record drive of the French high-speed train TGV in 1981. In 1988, the ICE-V sets a new world record speed for rail vehicles of 406 km/h – with a newly developed brake system comprising microprocessor control, high-performance disc brakes, and electromagnetic eddy-current brakes.

to

DB 60 direct-release control valve for US freight trains

In the 1980s Knorr-Bremse develops a brake system for freight trains with the latest valve technology in accordance with the AAR standards, which apply throughout North America. In view of the special operating requirements, the DB-60 distributor valve is designed is designed for direct release. The company uses its US subsidiary Knorr Brake Corporation, founded in 1973, to gain the necessary contacts in a market to which it has hitherto had little access. The DB 60 direct-release control valve receives AAR approval in April 1985. Knorr-Bremse thereby conquers one of the world’s largest rail vehicle markets. Over time, this step also gave the company access to the South African market, which uses the same standard.

Management Buy-Out by Heinz Hermann Thiele

Following disputes between the owner families, Knorr-Bremse finds itself in a leadership crisis in 1985. In a management buy-out, Heinz Hermann Thiele acquires the majority of the shares previously held by Dr. Jens von Bandemer and gradually becomes sole owner of Knorr-Bremse. He has already been active in the Group for over 15 years, most recently as Commercial Manager. Knorr-Bremse GmbH merges with Süddeutsche Bremsen AG to form Knorr-Bremse AG. Heinz Hermann Thiele, as chairman of the Executive Board, introduces far-reaching structural changes and concentrates the business on its core activities. Together with the company's international orientation, the focus on the two divisions, Rail Vehicle Systems and Commercial Vehicle Systems, that Thiele initiated make Knorr-Bremse the world's leading manufacturer of braking systems in both sectors.

First use of screw compressors in rail vehicles

The first screw compressors are in operation with customers as of 1985; various operators then soon use further screw compressors. The main benefits are quiet, low-vibration operation and pulsationfree supply of compressed air.

Pneumatic disc brake

At the International Motor Show in Frankfurt, Knorr-Bremse presents a prototype of a pneumatic disc brake for commercial vehicles that attracts widespread interest. 20 million Knorr-Bremse disc brakes are now in operation all over the world.

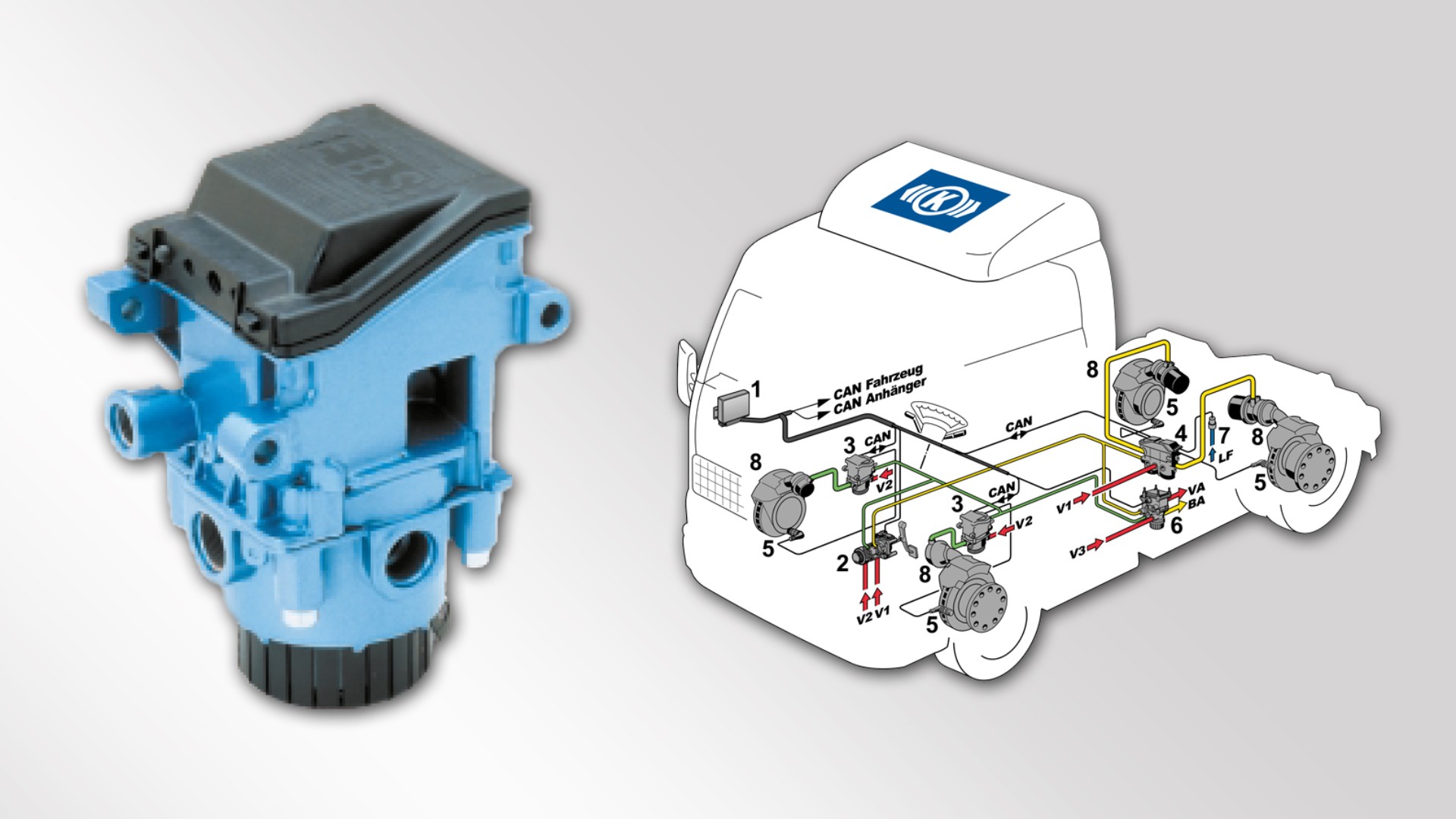

EBS Electronic Braking System for commercial vehicles

The EBS integrates the brake control, anti-lock braking system (ABS) and traction control system (TCS) into a single electronic system. The advantages compared with pneumatic control include shorter response times and reduced braking distance – which means greater safety.

Joint Venture with VEB Berliner Bremsenwerk

Even before the reunification of Germany, Knorr-Bremse and VEB Berliner Bremsenwerk, the successor company to the old Knorr-Bremse AG in Berlin, establish the first East-West German stock corporation "Berliner Bremsenwerk - Knorr-Bremse AG" (BBW-KB AG) to support the process of reform in the GDR. The VEB Berliner Bremsenwerk, with which license agreements had been in place since 1959, produced braking equipment for rail vehicles and commercial vehicles at its old headquarters in Berlin-Lichtenberg with around 1600 employees. In 1991, Knorr-Bremse takes over the company completely, creating Knorr-Bremse AG. After more than 46 years, Knorr-Bremse is once again represented in Berlin with its own plant.

Takeover of New York Air Brake Corporation (NYAB)

In 1991 Knorr-Bremse takes over New York Air Brake Corporation (NYAB), thereby paving the way for further expansion of its market share in the USA and Canada. Brake systems are developed together with NYAB, above all for long, heavy freight trains with the coupling of several locomotives, as is frequently required.

The dawn of the ICE era – with high-speed braking systems

The electro-pneumatic independent brake is further improved and installed in the ICE 1 high-speed train.

Start of production of the pneumatically activated disc brake for trucks

Knorr-Bremse presented the prototype of a pneumatically activated disc brake at the IAA in 1987, and in 1992 the company starts production. Worldwide distribution finally begins with series deliveries to Daimler and Scania in 1996. Disc brakes in place of drum brakes make for low weight, compact installation, cost savings, and increased safety.

Legally independent companies for the two divisions

The two divisions become two separate companies as strong, independent pillars: Knorr-Bremse Systeme für Nutzfahrzeuge GmbH (Commercial Vehicle Systems) and Knorr-Bremse Systeme für Schienenfahrzeuge GmbH (Rail Vehicle Systems). This restructuring marks the start of a rapid process of international expansion and strong growth that has continued ever since.

Electronic braking system (EBS) for commercial vehicles goes into series production

EBS integrates safety functions such as ABS (anti-lock braking system), TCS (traction control system), load-dependent braking, and coupling force control for trailers – the truck can be safely controlled independently of load, road conditions, or speed. The electronic control replaces the previous pneumatic version, thus enabling quicker response and shorter braking distances, and enhancing safety.

Knorr-Bremse Far East Ltd. established in Hong Kong

Knorr-Bremse Far East Ltd. is established in Hong Kong in 1994 to increase global presence in both the rail and commercial vehicle sectors. Heinz Hermann Thiele already recognizes the great significance of the Chinese market in 1989 and signs the first major contract in China: Knorr-Bremse supplies the brakes for the Shanghai metro system.

Expansion of the on-board product portfolio for rail vehicles with IFE

In the late 1990s Knorr-Bremse starts to systematically extend its business field of on-board systems in the Rail Vehicle Systems division. An important impulse in this area is provided by the participation in the Austrian company IFE AG, a leading manufacturer of automatic door systems. The entire company is taken over and successfully internationalized in 2002.

Innovation for long freight trains: EP-60 Electropneumatic Distributor Valve

Knorr-Bremse supplies the newly developed EP-60 distributor valve for miles long freight trains in America, Australia, and South Africa. The signals are no longer pneumatically transmitted along the train, but much more rapidly by electronic means. This leads to lower longitudinal forces, shorter braking distances, and energy savings. After its first commercial use in Canada in 1998, the EP-60 is approved for the entire AAR market in 2004.

Joint venture with Bosch for commercial vehicle brakes

The company can now draw on the electronics expertise of the commercial vehicle brakes division of Robert Bosch. As a result, Knorr-Bremse AG and Robert Bosch GmbH, formerly competitors, become joint stockholders of Knorr-Bremse Commercial Vehicle Systems and cooperate in the field of air brakes for commercial vehicles. This alliance strengthens the two partners’ competence as suppliers of complete systems on the global market.

Takeover of Westinghouse Brakes and Mannesmann Rexroth

Knorr-Bremse consistently pursues the aims of consolidating its brake business and strengthening its position as a systems supplier. For this purpose the rail technology division of Mannesmann Rexroth Pneumatik KG is taken over, along with the brake and platform door divisions of Westinghouse, a company rich in tradition and active in the United Kingdom and Australia.

Takeover of Bendix in North America

Knorr-Bremse has been cooperating with Bendix Corporation in a joint venture since 1993. Bendix is one of the leading manufacturers of air brakes and ABS anti-lock braking systems for commercial vehicles in North America. In 2002, Bendix is taken over entirely. Knorr-Bremse thereby decisively strengthens its position on this market and continues to consistently deploy its system strategy worldwide.

Electronic Air Treatment EAC series delivery to Renault Trucks

EAC is a flexible mechatronic system for the supply of compressed air. Its intelligent control and its communication with the vehicle’s CAN enable a number of additional functions as compared with conventional devices. Series delivery to Renault Trucks in 2004 marked the beginning of its successful marketing.

Foundation of the non-profit organization Knorr-Bremse Global Care

In response to the tsunami disaster in Southeast Asia in December 2004, the charitable organization Knorr-Bremse Global Care e. V. was founded at the beginning of 2005. The aim was to provide rapid an efficient aid to the victims of this flood disaster. Following the successful implementation of the first selected aid projects, Knorr-Bremse Global Care continued its work around the world, constantly expanding and professionalizing its activities. To this day, the non-profit organization supports people who, through no fault of their own, are in need as a result of environmental disasters, war, poverty or disease. The support focuses on the areas of education, water, sanitary and hygiene (WASH), and emergency aid.

On-board reinforcements with Merak and Microelettrica

With two takeovers, Knorr-Bremse strategically extends its on-board product range for rail vehicles: Merak is a specialist for heating, ventilation, and air conditioning (HVAC) equipment; Microelettrica Scientifica provides electromechanical and electronic switching and control components for energy management.

Mechatronic Brake Control System EP2002 for metros

Thanks to its decentralized control units, this compact mechatronic brake system for electronically controlled air brakes reduces installation space and weight. The system was first tested in the Munich metro in 2001. EP2002 considerably increases availability of trains and enables them to run at shorter headways.

Extending presence in China

Knorr-Bremse has maintained contacts with China since the early 1980s. At the beginning of the new millennium, the Group consolidates its position on a rapidly growing market with joint ventures and its own production plants. By concentrating on local development, production, sales, and export, Knorr-Bremse establishes itself as a Chinese manufacturer.

to

Expansion of the market position in the rapidly expanding Russian truck market

Knorr-Bremse first gained access to the Russian truck market in 1995. Back then it was still operating from its Hungarian base, but a new joint venture set up in December of last year with KAMAZ has now enabled the company to adopt a different approach. KAMAZ is the largest commercial vehicle manufacturer in the CIS states and is currently achieving high double-digit growth rates for vehicle production. From their base in Tatarstan, Knorr-Bremse and KAMAZ are together embarking on an exciting new project aimed at improving drum brakes and introducing the disc brake to Russia.

Joining the UN Global Compact and adopting a corporate responsibility strategy

Knorr-Bremse joins the UN Global Compact and thereby commits to ten globally recognized core values in the areas of environmental protection, labour standards, human rights and anti-corruption. The company also adopts a group-wide corporate responsibility strategy that anchors corporate responsibility and sustainability in the corporate strategy.

Screw compressors for Volvo

Knorr-Bremse delivers screw compressors for Volvo hybrid buses. Unlike the piston compressor for diesel vehicles, which is directly linked to the drive engine, this compressor is electrically operated. Thanks to its design, vibrations are considerably reduced and noise levels minimized.

Takeover of Sigma, Anchor and Icer Rail

With the takeover of Sigma Transit Systems, Knorr-Bremse consolidates its product range in HVAC technology for Asia-Pacific. In the field of friction materials, Knorr-Bremse acquires Anchor Brake Shoes in the USA and Icer Rail in Spain, thereby entering into the development and production of brake pads and blocks for rail vehicles.

Certification for a specific distributor valve for the Russian market

In Russia, very long and, above all, heavy freight trains that transport goods, including many raw materials, on over 85,000 kilometers of track every day have to be braked. The resulting longitudinal forces must be controllable at all times. This is one reason why the UIC test standards commonly used in Europe do not apply to the Russian market. In addition, harsh winters with temperatures as low as -55 °C demand special product requirements. Knorr-Bremse has therefore developed a specific control valve that will be approved in Russia in October 2011.

Opening of the Value Stream Academy

The Group-wide Value Stream Academy is opened at the Czech site in Liberec. The new training center promotes improvements across the entire value stream and provides Knorr-Bremse employees with the necessary theoretical foundations.

New corporate values at Knorr-Bremse

Knorr-Bremse introduces new corporate values: “Entrepreneurship”, “Technological Excellence”, “Reliability”, “Passion” and “Responsibility”. They describe what Knorr-Bremse is all about. The new values stand for clear identification features and for the strengths of the Group, for fair cooperation both internally and externally. They provide all employees worldwide with a framework that guides their daily actions and decisions.

Sales increase to over five billion euros

Customers appreciate the great commitment, reliable products, and perfect service from Knorr-Bremse: In 2014, sales jump to over 5 billion euros for the first time – an increase of over 20 percent over the previous year’s figure. Knorr-Bremse achieves a major portion of this success on the Asian market.

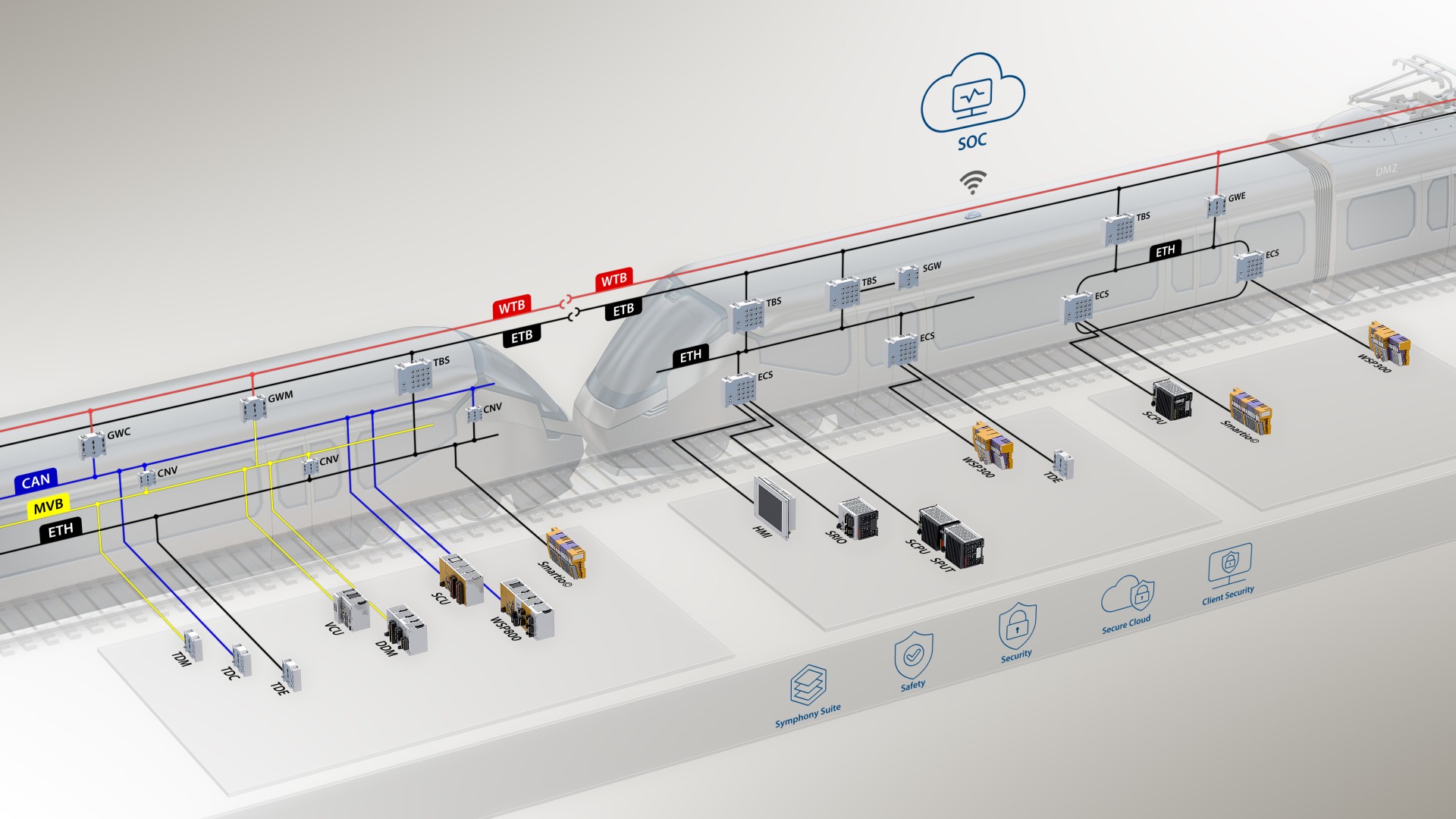

Vehicle control systems from Selectron

Today, advanced control systems are indispensable for modern rail vehicles. In Selectron Systems AG, Knorr-Bremse takes over a recognized specialist for train control and communication systems with flexible solutions and components for the automation, networking, and control of rail vehicles.

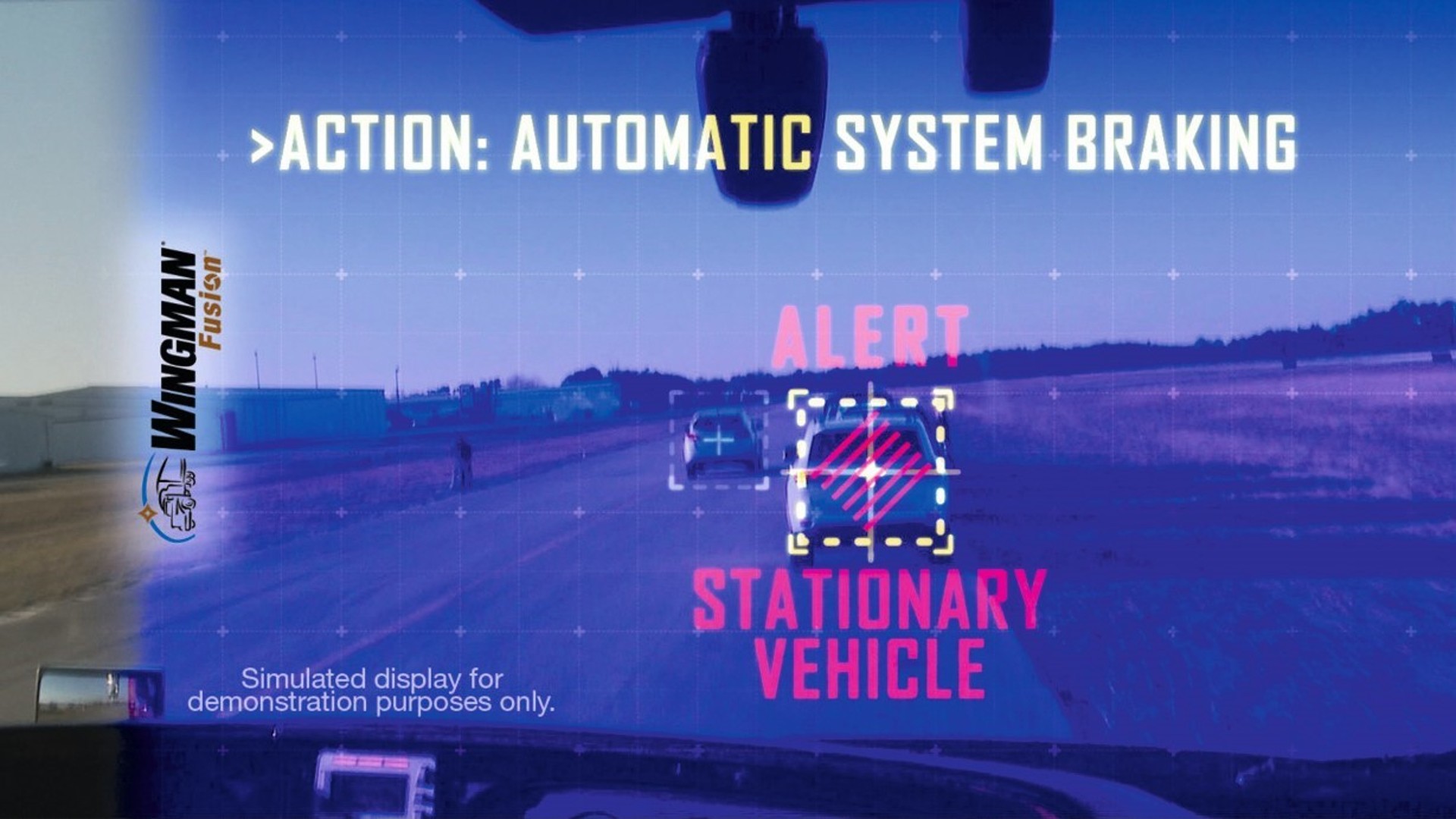

Introduction of Wingman Fusion® in the USA

In the USA, the Knorr-Bremse subsidiary Bendix introduces the first Advanced Driver Assistance System (ADAS) for commercial vehicles on the market. Wingman Fusion® integrates the information from the camera, radar, and the brake system to yield a detailed, accurate picture of a vehicle’s entire surroundings, thereby also enabling important security features.

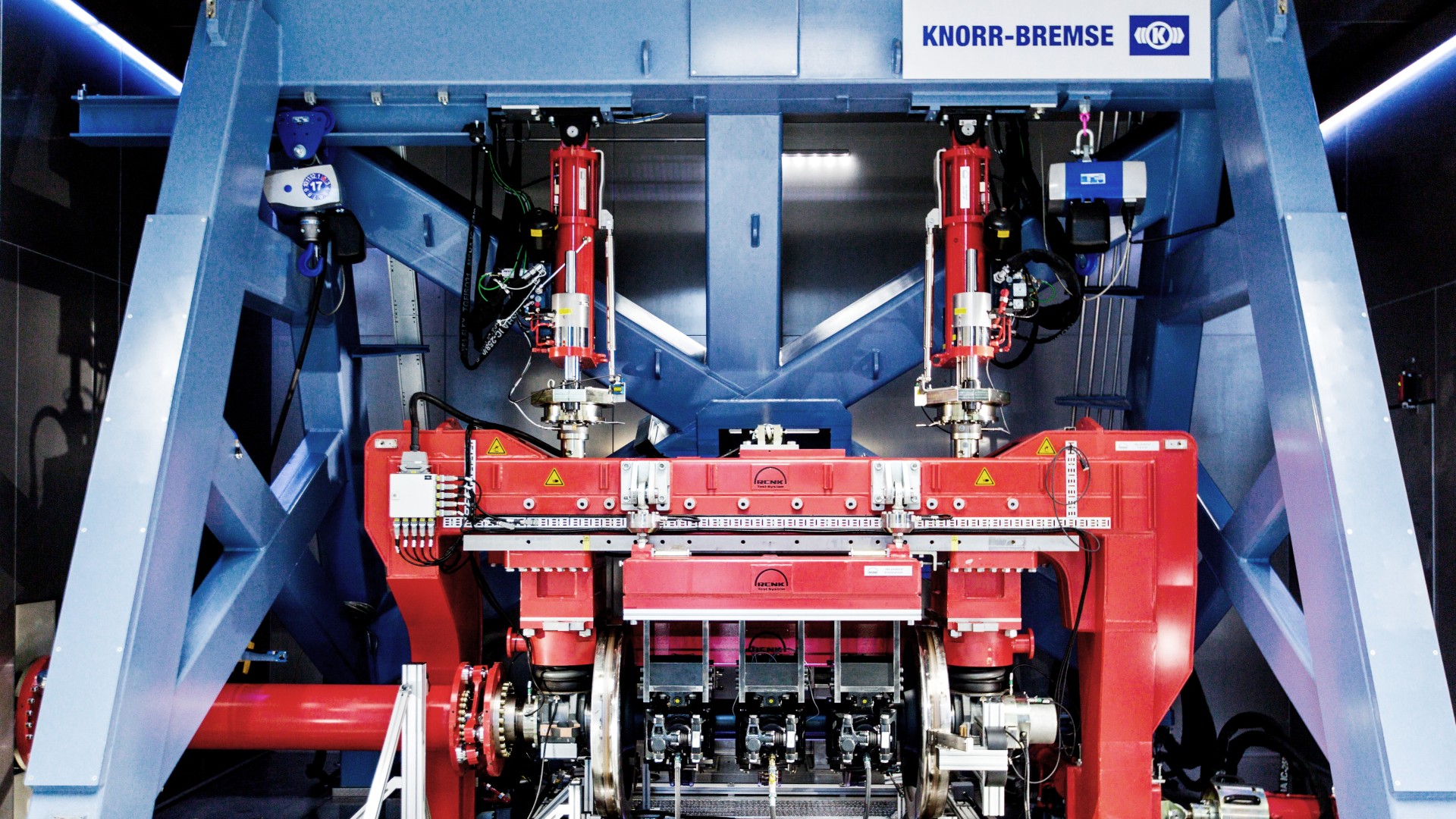

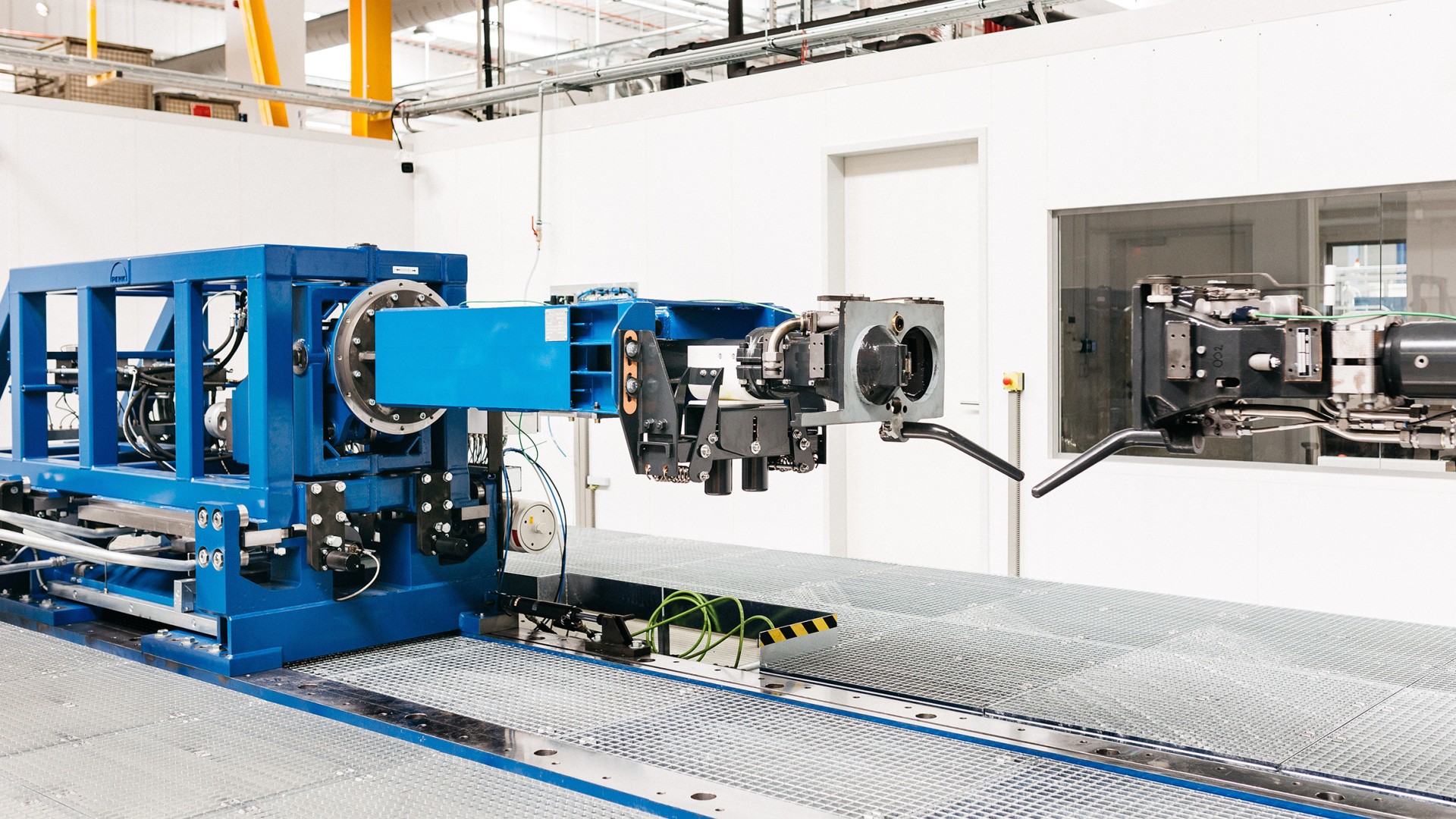

Munich Deveoplment Center opens

Knorr-Bremse opens a new Development Center covering an area of almost 17,000 square meters at its Munich site. With more than 100 different test rigs and dynamometers, the new Center provides state-of-the-art conditions for the development and testing of innovative braking systems and components for the rail and commercial vehicle markets. Several hundred engineers from both corporate divisions are working there on future technologies on an interdisciplinary basis. At over 90 million euros, this is the largest single investment in the company's history to date.

Launching into steering systems

Braking and steering are key elements of autonomous driving. With the takeover of tedrive, Knorr-Bremse extends its portfolio with the addition of steering technologies, in order to offer economical system and redundancy solutions on the growing market for driver assistance systems and automated driving by means of intelligent networking with efficient architectures.

First autonomously driving tractor-trailor from Knorr-Bremse

Knorr-Bremse presents an autonomously driving tractor-trailer combination at the IAA 2016. The truck is virtually handed over the to the scheduler, then drives to the loading ramps designated by the scheduler and returns to the driver at the delivery point. The recognition of the vehicle’s surroundings by sensors and its GPS positioning enable safe, driverless maneuvering on the truckyard.

Vossloh Kiepe takeover integrates e-drive competence

Knorr-Bremse incorporates Kiepe Electric, a globally active supplier of systems and components for electric drive solutions in rail vehicles and electric buses. Energy management, charging technology, and vehicle integration round off the product range.

CCB-3 modular loco brake control kit presented

Knorr-Bremse presents the CCB-3 modular loco brake control kit, developed for all major worldwide rail specific standards such as UIC, AAR, or GOST. Thanks to its modular design, vehicle manufacturers that offer their locomotives throughout the world are provided with standardized solutions. This reduces the effort for country-specific adaptation.

Knorr-Bremse goes public

Knorr-Bremse AG makes a successful start on the Frankfurt Stock Exchange on October 12th, 2018. A total of around 48 million shares are placed. With a volume of almost 4 billion euros, this is Germany’s second-largest stock exchange launch of the year.

LEADER® Autopilot™ Automation System for trains

The American Knorr-Bremse subsidiary New York Air Brake demonstrates fully automatic operation of a pneumatically braked freight train with LEADER® AutoPilot™. In addition to braking, the system also controls the traction system and can accelerate, slow down, and stop the train.

to

Heinz Hermann Thiele passes away

Heinz Hermann Thiele, majority shareholder and long-time Chairman of the Executive Board and Supervisory Board of Knorr-Bremse AG, passed away on February 23, 2021, at the age of 79, in Munich.

Through his entrepreneurial vision, in more than 35 years he built up the Knorr-Bremse Group from a medium-sized company in a difficult economic situation into a profitable, globally successful corporation with almost 30,000 employees and annual sales of around EUR 7 billion.

In 1969 he began his career at Knorr-Bremse as a legal clerk in the patent department. From 1975, Thiele was entrusted with the development and expansion of the Commercial Vehicle Systems division, and in 1979 was appointed to the company's Executive Board, where he served for 28 years. In 1987, he became Chairman of the Executive Board of the Group, whose shares he successively acquired from 1985 onward. From 2007 to 2016 Thiele was Chairman of the Supervisory Board of Knorr-Bremse AG, and from July 2020 Deputy Chairman. In 2016, Heinz Hermann Thiele was appointed Honorary Chairman of the Supervisory Board.

Please find in our online magazine a detailed article about his unique and extraordinary life’s work: Looking back on the great life's work of Heinz Hermann Thiele

Knorr-Bremse is founding member of Europe’s Rail Joint Undertaking

Knorr-Bremse is one of 25 founding members of the newly formed Europe’s Rail Joint Undertaking technology initiative (ERJU) , which continues Shift2Rail, a European rail research program for rail transport. Knorr-Bremse lays the foundations of next-gen rail transportation technology in five Flagship Areas: autonomous train operation, digital freight transportation, sustainable green solutions, digitalization, and life-cycle management.

First prototype of the Digital Automatic Coupler (DAC)

Knorr-Bremse is producing the first prototypes of its Digital Automatic Coupler (DAC), which will enable automation features and intelligent, digital services for rail freight transportation. Safety, robustness and performance have the highest priority: Made of special steel, the coupling system can withstand the enormous torsional and longitudinal forces that occur when freight trains drive, brake and maneuver. At the same time, Knorr-Bremse has focused on efficient maintenance and optimized life cycle costs of the DAC. Overall, the Knorr-Bremse DAK is an enabler for automation functions on the train as well as for digital services.

Investment in digital and data-driven aftermarket solutions for commercial vehicles

Knorr-Bremse acquires a majority stake in the Spanish company Cojali S.L. to expand its position in the field of digital and data-driven aftermarket solutions. Cojali is a globally successful developer and manufacturer of multi-brand diagnostic solutions for commercial vehicles. Among other things, Knorr-Bremse is thus expanding its existing aftermarket business with a commercial vehicle-specific software solution in order to open up new business areas in the field of big data and predictive maintenance in the future.

Knorr-Bremse enters the North American rail signaling segment

Knorr-Bremse acquires the North American conventional rail signaling business of Alstom Signaling, entering the signaling technology business (CCS: Control, Command and Signaling) in North America. Now known as KB Signaling Inc., the move expands the company's rail infrastructure electronics and digitalization availability. It is a significant step for the Knorr-Bremse global Rail Vehicle Systems (RVS) division and the North American rail group to transform from a vehicle system supplier to a supplier of mission-critical systems for the entire rail ecosystem.

Launch of the European Rail Data Space

Knorr-Bremse and eleven other rail industry leaders announce the launch of the European Rail Data Space (ERDS). The aim of ERDS is to create a common data space in which all rail sector stakeholders - from system suppliers, train manufacturers, operators and local transportation companies to ticket service providers - can exchange data seamlessly and securely. The new data ecosystem is being created as part of the Europe's Rail funding program and is being developed by a Europe-wide consortium under the leadership of Knorr-Bremse.