The relaunch of freight transport by rail is firmly priced into the European Green Deal: from just 18 percent today, its share of goods transport is meant to rise to 30 percent – by 2030. With its Digital Freight Train (DFT) solution package, Knorr-Bremse is putting the necessary technologies on the rails. They signal the start of a new era.

When a freight train is assembled anywhere in Europe today, the process could best be described as a glimpse into the history books. Shunting supervisors stand between the freight cars, latch screw couplings into train hooks and connect brake lines. Other tasks, such as the obligatory brake test, are also carried out manually. The shunting supervisor walks down one side of the train and checks each individual brake, all the way to the back. Then they make their way down the other side, walking all the way to the front. Hours can go by before the train is ready to depart. In principle, not much has changed in 130 years. Until now, that is.

“For rail to live up to its role as the backbone of mobility, it has to become more efficient, more available, more connected and more flexible,” says Dr. Jürgen Wilder, Member of the Executive Board and responsible for the Rail Vehicle Systems Division of Knorr-Bremse AG. “Digital technologies are the proverbial key that fits the lock of this task.” But freight cars, specifically – the backbone of environmentally friendly goods transport by rail – remain firmly in the analog world, typically running without electricity, without internet, without GPS.

Too slow, too sluggish, too expensive, too cumbersome, too rigid

The European Union (EU) has big plans for rail freight transport. As part of the European Green Deal, it wants to increase the share of freight moved by rail from 18 percent today to 30 percent by 2030. After all, there is no greener mode of transport than rail. And no other means of transport can achieve a 100 percent share of renewable energies as quickly as rail, thanks to regenerative braking. Expressed in tonne-kilometers, a truck emits roughly six and a half times more greenhouse gases than a freight train.

For rail to live up to its role as the backbone of mobility, it has to become more efficient, more available, more connected and more flexible. Digital technologies are the proverbial key that fits the lock of this task.

Dr. Jürgen Wilder – Member of the Executive Board and responsible for the Rail Vehicle Systems Division of Knorr-Bremse AG

Yet the EU’s 30 percent target comes with a clear condition: freight transport by rail must become substantially more competitive. Non-automated processes, for example in train preparation, currently make it too slow, too sluggish, too expensive, too cumbersome, too rigid.

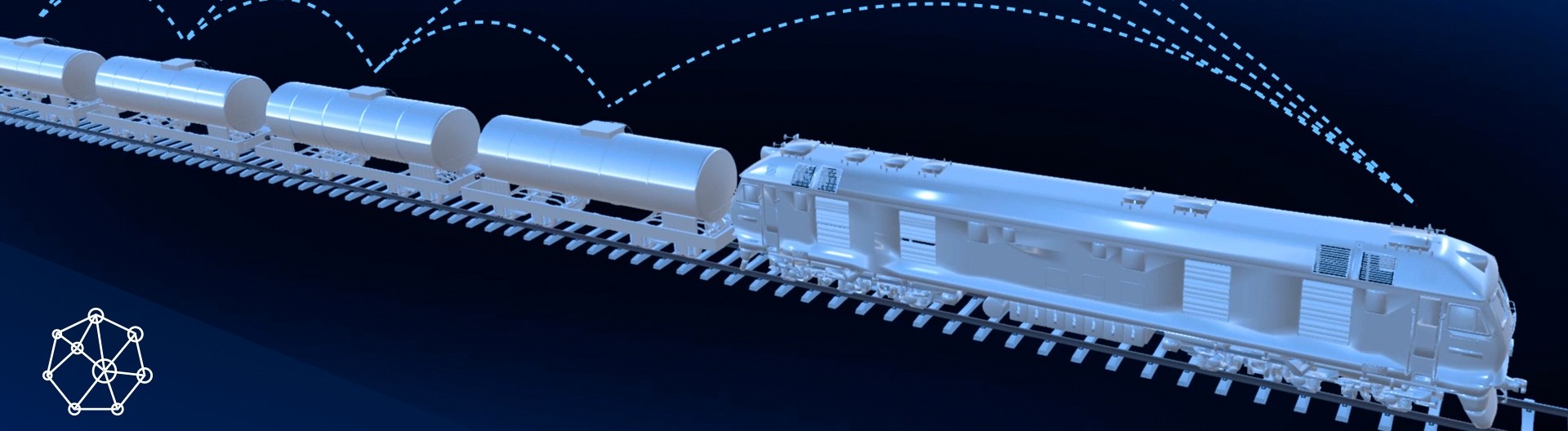

The fact that Knorr-Bremse is investing so heavily in its Digital Freight Train is no coincidence. The Digital Freight Train is the crucial lever in achieving the 30 percent target. Starting with the individual freight car, automated processes and digital solutions will increase transport capacity, efficiency and availability. This should ultimately give rise to intelligent, intermodal fleet operations, with individual transport orders finding the fastest route to their destination as if by themselves. A sleeping giant will soon be awakened.

The developers are focusing on three main areas of action: the car, the train, and the train configuration. Because only a smart, automation-capable car can enable the whole train and fleet to run intelligent and automated processes.

Technological trio of digitalized freight cars, Digital Automatic Coupling, and a new braking system

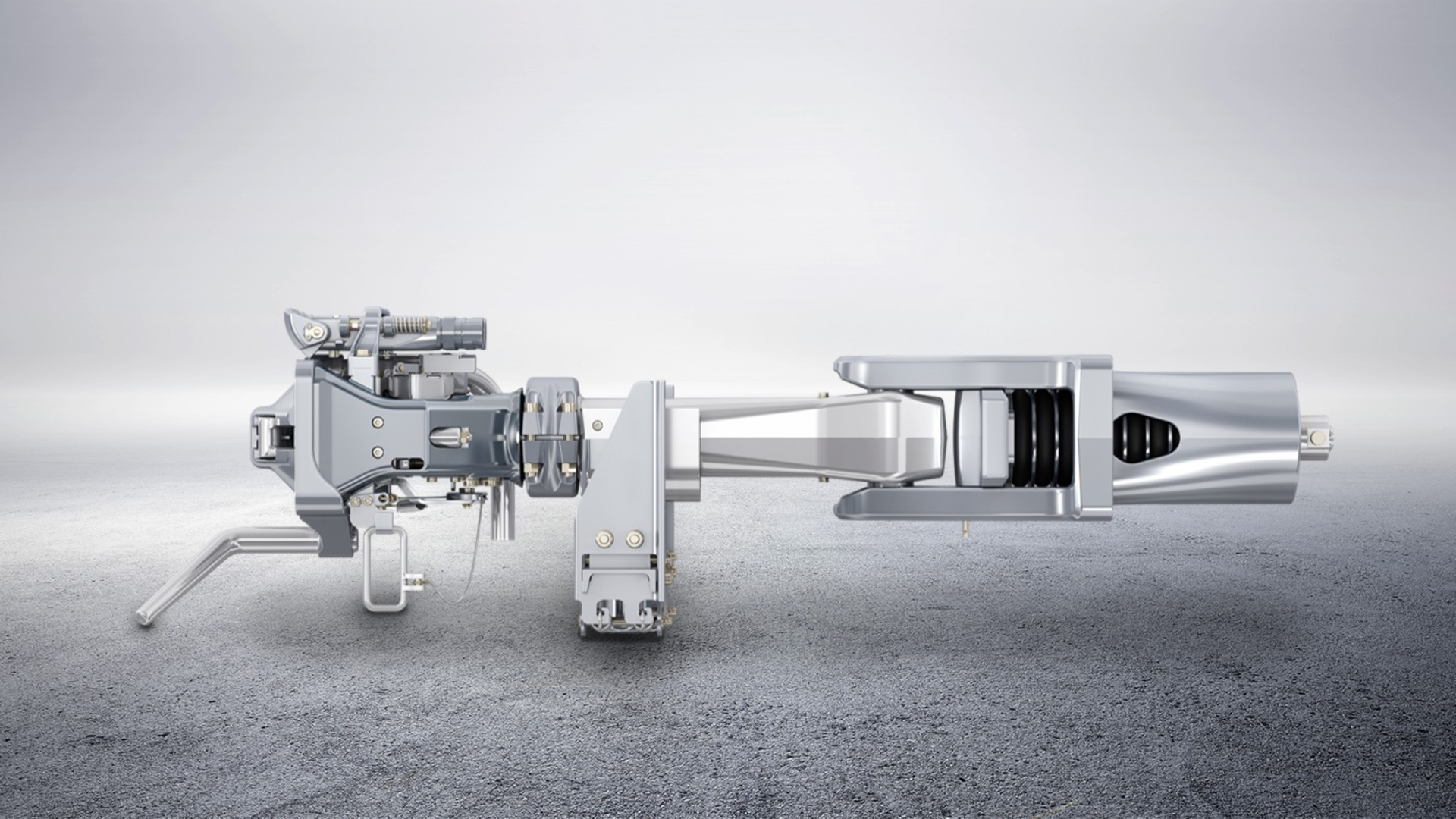

The first “building block” is FreightLink, the Digital Automatic Coupling (DAC). This technology, which has long been standard in passenger transportation, is now set to automatically attach freight cars to one another. This involves more than just mechanical coupling or connecting compressed air pipes. New lines for power and data signals will also be connected automatically in future – thus laying an essential foundation for intelligent, automated and intermodal freight management.

At the car level, FreightControl comes into play, an electronic hardware and software solution for digitalized freight cars. Not only would this step soon make condition-based maintenance available to freight cars on a large scale. It would put the industry in a position to also adopt digital or automatic brake testing for freight trains.

Freight consignments from different logistics companies with the same destination or the same route sections could also be proactively combined and transshipped in a planned manner thanks to GPS location. The laborious processes involved in today’s freight car operations would be significantly shortened.

Looking ahead, this is a compelling argument: if Digital Automatic Coupling, automated brake testing and intelligent environment detection all work together, this also allows shunting systems to function in a highly automated manner.

“The most important thing is that the political will persists”

At the train level, Knorr-Bremse is working on the future electropneumatic braking system (EP brake). Its development comes in light of the fact that European freight trains do not yet have any electronics on board – braking relies exclusively on pneumatic technology. The braking signal and braking energy are transmitted at the same time – by compressed air. However, there is always a major drawback: the braking signal spreads only gradually along the train. While the front cars are already braking, the rear cars are still shunting the train along.

The electropneumatic braking system of the future takes a solution from passenger rail and adapts it. Equipped with electric lines, braking and control signals will also be transmitted electronically along the length of freight trains. Only at the bogies will the brakes be applied pneumatically – and at virtually the same time. This will make a substantial difference when it comes to increasing rail freight capacity, as it will allow longer and heavier trains to travel faster while maintaining the same braking distance.

“The transition in freight transport is a mammoth task,” says Wilder. But technology is only one of the factors. “The most important thing is that the political will persists. I think all the investments in the rail sector are entirely correct, as they will enable us to combine much-needed economic growth with climate protection measures.”

The digital freight train

Rail freight is key to meeting ambitious climate targets and to the sustainable transportation of goods. Freight trains must be energy-efficient, cost-effective and quiet, while also making extensive use of digital technology to enable a higher degree of automation. Knorr-Bremse supplies modular solutions that can be customized to each operator’s specific requirements.

For further information, please visit the website of our Rail Vehicle Systems division .