Globally present, locally anchored: With customer proximity and market focus, RailService has transformed itself from a spare parts supplier to a comprehensive business partner.

Sell, deliver – then just disappear? That’s not how the global rail technology market works. Train fleets are expected to run for decades – safely, economically, energy-efficiently. And Knorr-Bremse’s long-term service solutions help them to do so. In this interview, Kathrin Moder, Director RailServices, discusses the nature and prospects of this dynamic, growing market.

From “spare parts store” to strategic systems partner

Kathrin Moder has been a driving force behind the steady rise of Knorr-Bremse RailServices. Over the last decade, as Director RailServices, she and her colleagues have taken the global service network to new technical and commercial heights. The challenges of the job have also fueled her personal growth.

Mrs. Moder, ten years ago, why were you so sure that RailServices would evolve successfully?

Kathrin Moder: Even then, delivering train technologies and servicing them were two sides of the same coin. But the Rail division was focused on the strong primary market – on equipping new trains with our systems, such as brakes. RailServices was mainly involved in supplying the spare parts needed by operators to keep the various technologies up and running over the long term. It was already a solid business back then, but the real innovations were coming from other departments. At the same time, it was obvious that RailServices had the potential to become an exciting and exceptionally promising area of activity, with plenty of scope for development. And we’ve steadily worked on realizing this potential. Today, our service business is responsible for at least half of the Rail division’s global revenues.

How did you go about expanding the business?

For a long time, spare parts and maintenance were our key service offerings. Operators had – and still have – a mindset that’s primarily focused on train availability, so on trains that run safely and reliably. But over time, they started to think about other high-priority needs, such as greater environmental compatibility, extended service lives and optimized processes. We responded to these broader considerations and in doing so, evolved from a simple supplier into a serious business partner. And of course building deeper relationships with our customers also involves taking more responsibility.

… which in turn can have a positive effect on new business?

Exactly, because when train manufacturers and rail operators are satisfied with one project, they’re also happy to rely on Knorr-Bremse’s ability to find solid, dependable solutions for their other projects. We want our customers to know and feel that: “If we buy Knorr-Bremse systems, our rail vehicles will stay up and running.” Not just when they buy our core product, braking systems, but also when they’re looking to buy other mission-critical systems such as train doors, climate control systems and couplers.

Did you implement the “Sustain – Enhance – Accelerate” strategy in order to satisfy this demand for high train availability?

This three-point slogan essentially defines the RailServices mission. As a premium solutions provider, we want to bring our dependability and expertise to bear on our customers’ vehicles. So in the first instance, we “sustain” them by providing the technical solutions that will enable trains to stay operational over decades. That’s a sustainable approach in itself! Second, we “enhance” their fleets by helping to ensure that they’re always fully operational and ready to go, increasing train availability. And third, we work with our customers to optimize and “accelerate” their processes so their operations become faster, more efficient, and more economical.

Is this strategy – and the various solutions involved – global in scope?

As the division’s global headquarters in Munich, we develop the global framework and “product concept”, as it were. We then introduce them to our local sites as the basis for service offerings tailored to specific markets and regions. We regularly discuss new services, business partners and best practices, as well as changes and enhancements to our various services. Often, our local offices immediately spot a local need, or evaluate it and put forward their own ideas for satisfying it.

Kathrin Moder

“What our customers care about are safe, long-lasting, efficient fleets. As a service partner, we play a key role in delivering these outcomes.”

Guided by this principle, the team led by Kathrin Moder, Director RailServices, has steadily developed the business unit. Kathrin Moder gained her first impressions of the international service business – in those days, still very much focused on spare parts – while working at Knorr-Bremse as a student trainee. She started her professional career with the company in 2005, joining the RailServices unit in 2013.

Four action areas for meeting multiple customer needs

Knorr-Bremse RailServices has developed specific solutions across four action areas, all with a common goal: to make train fleets future-proof and highly efficient:

- Improving eco-efficiency and environmental friendliness (Environmental Improvements) involves, for example, retrofitting trains with technologies that help to save energy and avoid carbon and noise emissions, as well as wear and tear.

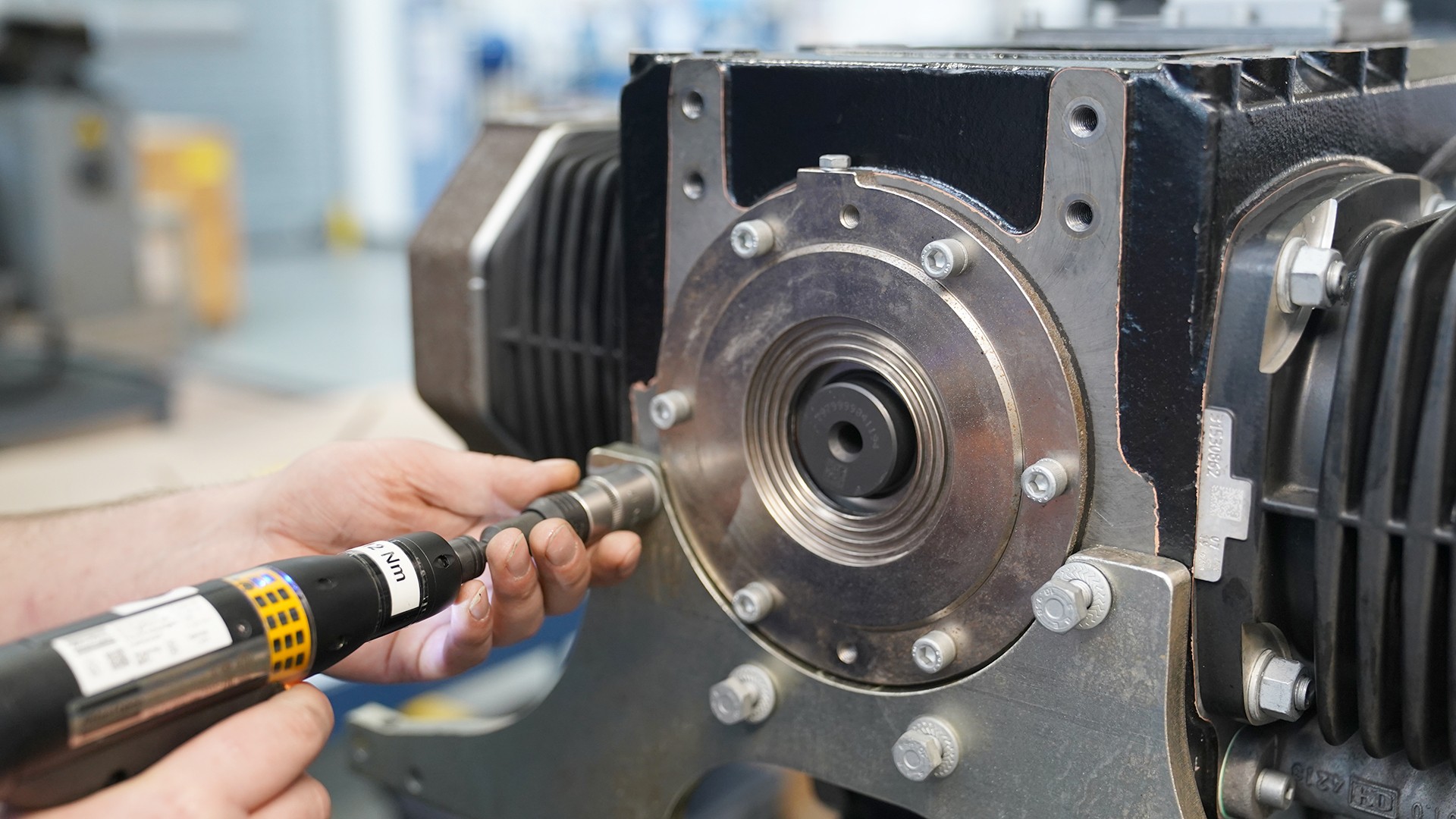

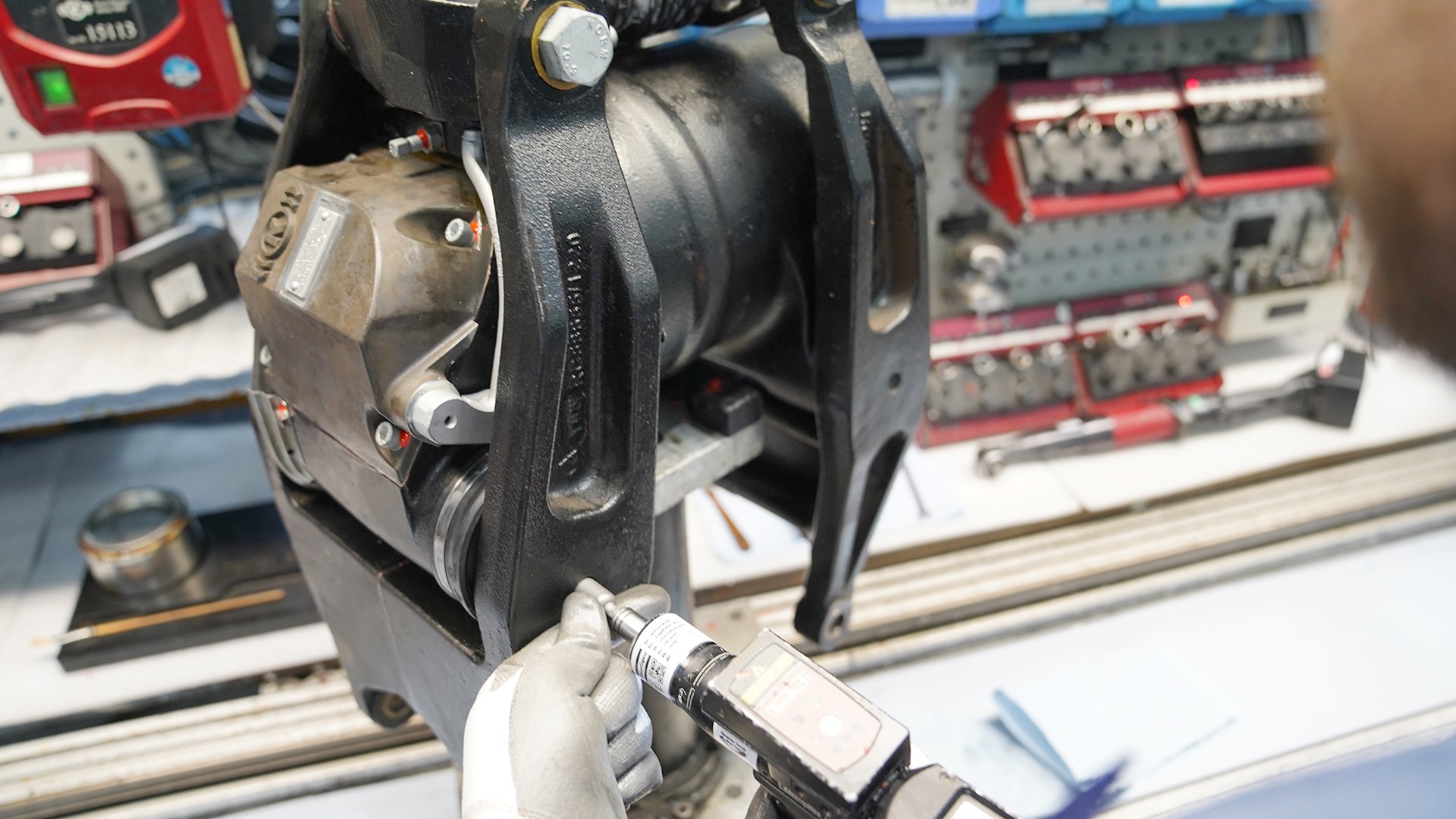

- Improving train availability (Availability Solutions) puts more trains on the tracks by assuring the long-term supply of spare parts and components.

- Optimizing processes (Process Optimization) means providing customers with comprehensive assistance, support and training so they can develop and enhance their own skills and processes for maintaining Knorr-Bremse technologies.

- Extending trains’ service lives (Lifetime Expansion) is done by creating, for example, customized solution packages for modernizing the onboard technologies already installed.

Are regions also accepting the services associated with these action areas?

The extent to which regions make use of our service offerings very much depends on local operators. Many of them carry out much of the servicing of onboard Knorr-Bremse technologies themselves, while others do less – depending on their resources, willingness and expertise. But of course there are regional preferences. In Europe, for example, there’s just as much demand for extending trains’ service lives as there is in the USA. Energy efficiency also plays an increasingly important role. In the USA, for example, rail freight operators are very interested in retrofitting trains with our driver advisory system, LEADER . This helps to ensure that extremely long, heavy freight trains traveling huge distances across the country run more energy-efficiently, accelerate more intelligently, and brake more safely. Europe’s rail freight operators are primarily interested in using the LEADER driver advisory system to save energy.

While the emerging Chinese market probably works differently?

Over the last 20-25 years, China has brought a lot of new trains to the market, so the country’s fleet is still very young. We see indications that China is increasingly thinking about how to keep this enormous stock of vehicles running for decades into the future. This is where Knorr-Bremse’s role as aftermarket partner comes into play. With our base of installed systems, China represents huge business potential in the service sector, and we intend to make the most of it in coming years. We’re also very interested in Chinese-manufactured trains equipped with our systems that are currently operating in other countries – mostly in Africa and South America.

The many different growth drivers

In saturated markets, new vehicles are generally replacements for older vehicles. But in China, the number of new vehicles is increasing, and is also expected to rise in India. This means that the stock of vehicles in need of servicing is also growing. But there are other, equally interesting growth levers.

What factors could further boost RailServices, aside from growing markets?

It might sound paradoxical, but the shortage of skilled workers in industrialized nations could actually drive further growth. By expanding our range of service offerings, we can take a lot of the work involved in train maintenance out of our customers’ hands and make the whole process of keeping trains in operation less complex. What’s more, it’s clear that cost efficiency and sustainability are key factors for operators. They need to keep a firm grip on costs and energy budgets, so they’re keenly interested in safe, long-lived, energy-efficient trains.

Can you give an example?

In particular, extending vehicle life cycles by modernizing or upgrading existing stock, or adding digital features, gives operators the opportunity to address the growing demand for mobility even as they systematically invest in new vehicles. We work closely with them, looking for ways to improve their vehicles. Here, environmental considerations also play a role. For example, climate control systems, which are vital for making travel attractive and comfortable, are the second largest onboard energy consumer after the main drive. Using our new, retrofittable solutions, you can cut energy consumption by up to 30% – while simultaneously improving performance.

Major expansion of service infrastructure

The dynamic growth of RailServices is also reflected in its steadily expanding footprint. This includes recently opened service hubs in Ankara, Budapest, Italy and Poland. In addition, the unit has successfully acquired and integrated two major local service specialists – DSB Component Workshops in Denmark, a unit with extensive experience of maintaining and repairing a wide variety of components, and Westcode , a service provider in the UK.

You’re continuously expanding your service network. Is this bringing you steadily closer to your customers?

Our infrastructure aims to deliver the best possible responses to our customers’ needs. With respect to service projects, operators prefer to work on a very local basis, because they’re often inviting tenders for regional contracts. To win these orders, deliveries – whether by us or by third parties – must often include a significant proportion of local content, that is, provide much of the added value in the country itself. That’s why our customers appreciate our local presence. As for your question about which of our service centers provide which services, other factors like process optimization, competitiveness and local expertise also play a role in this respect.

What advantages do you expect to gain from a new service center?

Our service center in Turkey is a perfect example of how we turned a customer and market trend into a successful business case. Previously, we provided our services to our Turkish customers from Germany, which on the whole worked reliably, albeit with sporadic language and handling issues. But by setting up a preliminary, small-scale service center in the country, we really familiarized ourselves with our Turkish customers’ requirements, so we were able to improve their vehicle availability. Coupled with our local presence, this successful work resulted in more intensive dialogue and a better understanding of our customers’ needs – regarding technical solutions for existing vehicles, for example. So for RailServices, this kind of interaction creates new opportunities, which causes the volume of business to grow – and in the case of Turkey, caused our modern service center to grow as well!

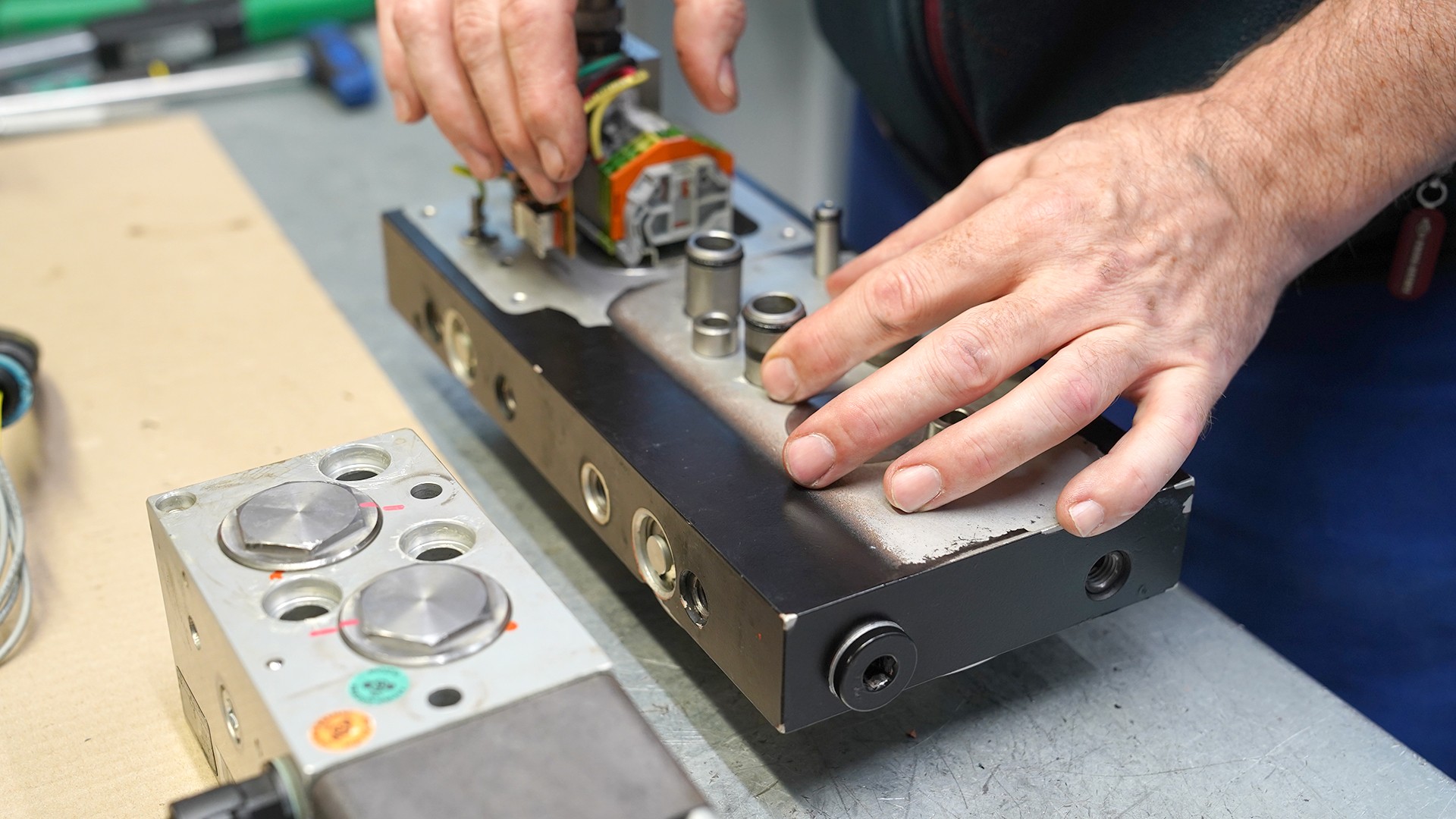

You now also service third-party components – isn’t this a challenge, or even a “hot potato”?

In any maintenance or modernization project, Knorr-Bremse systems must work alongside products from other providers. This also applies to equipment from other manufacturers for which the customer may not have been able to obtain any service, or at least not the level of service they wanted. That’s why we include third-party products in our own services – not a problem, thanks to our certified process and systems management expertise. We carry out well-established tests and inspections to ensure that third-party products are properly overhauled. Please note that none of this affects safety-relevant components!

Which recent project did you find really exciting?

There’s no question that our original equipment business in Egypt is especially exciting at the moment. Between now and 2026, we’re equipping high-speed and passenger trains – among others – with braking and entrance systems. Egypt is yet another emerging but highly promising market which RailServices is seeking to win over with our range of service offerings – a prospect I find highly motivating!