Rail, as a green mode of transport, has a key role to play in the transition to sustainable mobility. That’s why Knorr-Bremse is investing heavily in even cleaner systems for rail vehicles. Find out what the group has to offer in terms of alternative drive technologies for low-emission and energy-efficient mobility.

Attentive passengers get a pleasant surprise as the train pulls away – it’s all so quiet! The line is usually served by a multiple-unit train with a heavy diesel unit above the bogies. There’s no way around it, since there’s no overhead line. In technical terms, the line is not electrified. So diesel propulsion is the only way. Until now.

The vehicle accelerating out of the station in this scenario has neither a diesel drive nor an overhead line. Engineers at the Knorr-Bremse subsidiary Kiepe Electric have converted it to run largely on electricity. One of the two diesel units has made way for a large, high-performance battery unit. The control system switches to battery power on non-electrified sections of the route. These account for 40 percent of Germany’s entire rail network. If there is an overhead line, the control system draws power from it – and charges the batteries at the same time. This concept could soon be widely used on passenger trains.

This approach represents a genuine bridging technology to climate-neutral trains. On routes that used to be served exclusively by diesel power, operators are now running all-electric or using a maximum of 20 percent diesel power. In combination, the three energy sources of overhead line, traction battery and diesel generator bring huge savings in energy and CO2 emissions. This also stems from the varying degrees of efficiency. With electric traction under overhead lines, efficiency is as high as 80 percent. The battery-powered train is only slightly lower, at around 73 percent. The conventional diesel multiple unit, on the other hand, only achieves around 35 percent efficiency.

Germany’s interim target just nine years away

Soon, trains converted to electric drive will no longer be a novelty. In 2050, the EU aims to cross the threshold to climate neutrality and no longer be a net emitter of greenhouse gases. The urgency of the timeframe is made evident by an interim target from Germany: by 2030, greenhouse gases caused by the transport sector must be reduced by 42 percent compared to 1990. That’s under nine years from now.

Green deal with steel on steel, that’s the motto. It’s no coincidence that Knorr-Bremse is at the forefront of this development: “Knorr-Bremse was quick to respond to the trend toward sustainable and innovative transport solutions,” says Dr. Peter Radina, Member of the Management Board of Knorr-Bremse Rail Vehicle Systems and responsible for Kiepe Electric.

Knorr-Bremse was quick to respond to the trend toward sustainable and innovative transport solutions. In the process, we are using our decades of experience in equipping vehicles with electric systems and in e-mobility to engage in new fields of development.

Dr. Peter Radina – Member of the Management Board of Knorr-Bremse Rail Vehicle Systems and responsible for Kiepe Electric

“In the process, we are using our decades of experience in equipping vehicles with electric systems and in e-mobility to engage in new fields of development. We want to be a reliable partner for vehicle manufacturers and operators looking to equip their new vehicles with drive systems based on batteries or hydrogen. We are also pushing ahead with new development solutions such as the conversion of existing diesel multiple units to battery power, allowing the vehicles to operate for many years to come with sustainable traction technology on board.”

Charging while driving

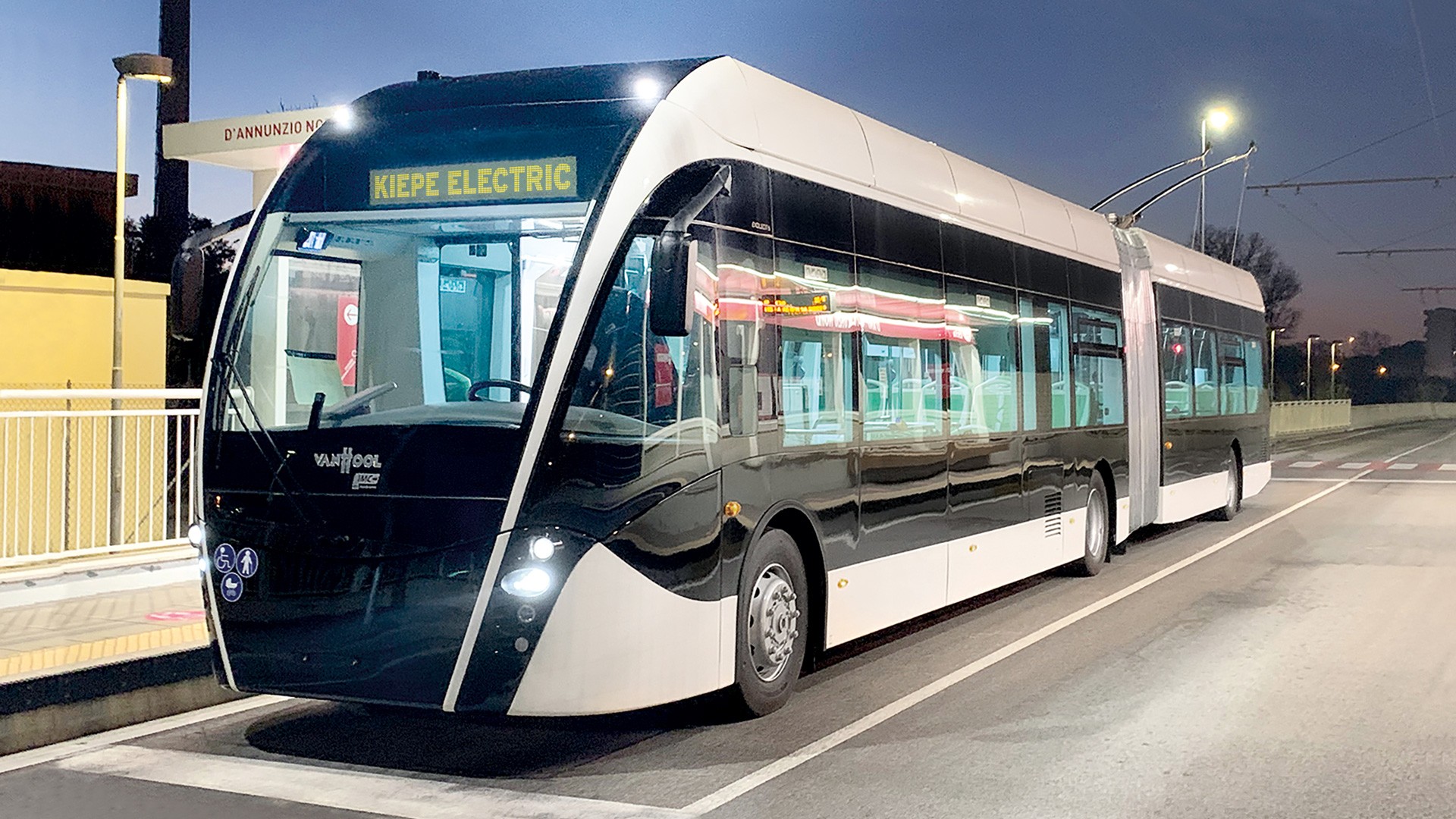

In addition, Kiepe Electric has developed an innovative drive concept for e-buses, which are noticeably expanding their share of the local transport mix, especially in medium-sized cities. For many years, the use of e-bus fleets was hampered by one crucial disadvantage: charging took too long. And because of the charging infrastructure required, there was a lack of flexibility in routing. IMC technology from Kiepe Electric eliminates both of these limitations. The acronym stands for In Motion Charging and refers to a hybrid concept for e-buses. On charging roads, the buses draw their energy from overhead lines while also charging their batteries, just like the converted diesel multiple units on rail lines. That means they have power stored up for sections of the route without overhead lines.

With the IMC500, currently the most powerful system on the market, a 12-meter bus only needs to be in contact with the charging road around 15 percent of the time. This gives the operating companies a great deal of flexibility when planning routes. If a new exhibition center goes into operation or a new housing development is occupied, they can simply adapt their routes to the latest requirements. Current IMC customer projects include Solingen in North Rhine-Westphalia, for example, where new IMC buses will replace diesel buses and serve sections of the routes without overhead lines. Also other international projects, such as in Rimini in Italy and Vancouver in Canada, demonstrate Kiepe Electric’s systems expertise for electric and efficient mass transit.

The e-bus is charged in just a few minutes

For cities that have no charging infrastructure at all, or where it is simply not economical to build it, Knorr-Bremse offers another diesel alternative: an electric drive system including traction batteries. Thanks to the smart interplay of several Kiepe technologies, these e-buses can recharge to a capacity of up to 750 kilowatts within a matter of minutes. The previous drawback that battery-powered e-buses may need an entire night to charge is thus overcome. The concept and technology are modular, scalable and suitable for vehicles from any manufacturer.

Looking beyond passenger transport, Knorr-Bremse continues to address the challenges of the climate crisis with sustainable solutions: the company now has a novel and deployment-ready process for converting heavy special-purpose vehicles from diesel hydraulics to fuel cell or battery power.

But that’s another story.