Germany's southernmost workplace is the Neumayer III research station in Antarctica. Keeping it supplied is a logistical challenge.

Info

All photos, except those of HASSE & WREDE, have the following copyright: © Alfred-Wegener-Institut / Ester Horvath (CC-BY 4.0)

Who hasn't heard the story of the race to the South Pole between the Norwegian Roald Amundsen and his English competitor Robert F. Scott? On 14 December 1911, Amundsen emerged victorious in the race. Scott only arrived at the South Pole 35 days later, and on the way back he would meet his death. The South Pole expeditions of that time were not only dangerous, they also involved lengthy preparations and immense logistical challenges. Robert F. Scott, for example, set sail for Antarctica on a whaling ship, with dogs and ponies on board, and took over two and a half years to reach the South Pole from his home port of Cardiff.

Even today, the journey to the icy south is a difficult and complex undertaking. "Antarctica is a place where you have to know what you're doing," says Doctor Tim Heitland, who managed the German research station Neumayer III from 2016 to 2018. That applies both to living in the southern polar region and transporting people and goods there. It takes four weeks just for the research vessel Polarstern to sail from the German port of Bremerhaven to the Neumayer station on the edge of the Ekström Ice Shelf in East Antarctica.

When the ship embarked on 20 December 2020, its cargo included ten to twelve freight containers of scientific equipment and spare parts weighing around 100 tonnes. It was also carrying six refrigerated containers with 55 tonnes of fresh and frozen provisions, plus fuel tanks for the station. All this is necessary because the station can only be supplied during the Antarctic summer, between mid-November and the beginning of March. After that, the current ten team members who remain at the station over the winter, known as "Üwis", are entirely on their own.

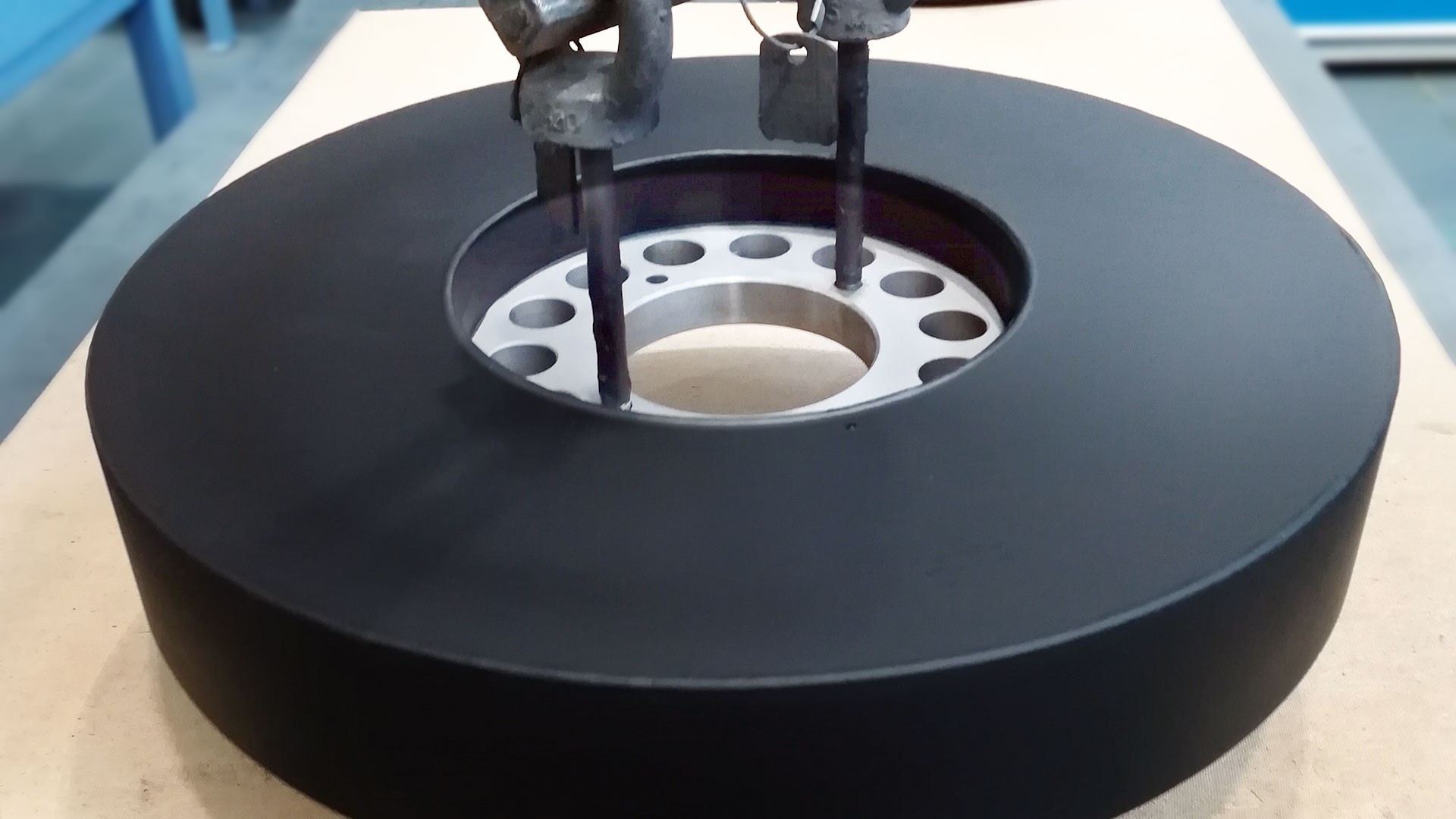

Before the Polarstern embarked last December, it underwent a thorough technical inspection. It is extremely important to ensure that the research vessel can withstand the extremes of cold weather and ice. Knorr-Bremse Group also played its part by completely overhauling two of the four viscosity torsional vibration dampers installed in the ship's four engines two months before it set off for the research station. HASSE & WREDE, a Knorr-Bremse subsidiary based in Berlin and a specialist in viscosity torsional vibration dampers for marine engines, took on the job.

We were delighted that our team in Berlin was able to overhaul two of the torsional vibration dampers on the Polarstern in the fall of 2020. The two dampers were at our factory for around a week while the work was completed. In the field of dampers for marine engine applications, we are one of the world's leading suppliers.

Markus Mali – Managing Director of HASSE & WREDE GmbH

The Üwis, who are flown in by aircraft under normal circumstances, are on board this winter as extra cargo. "Due to Covid-19, we decided to take them on the ship. Since it is sailing directly from its home port of Bremerhaven to Antarctica this season, we can be sure of arriving virus free," explains Heitland, who is now responsible for organizing the South Polar expeditions as Expedition Leader and Medical Coordinator at the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI) in Bremerhaven, which operates Neumayer III.

The further south the Polarstern ventures, the more demanding the voyage becomes. The Southern Ocean around Antarctica is notorious among seafarers for its storms. Moreover, many ships have been endangered by icebergs that have broken away from the ice shelf. The closer you get to the Antarctic continent, the greater the likelihood that the sea will freeze over. At this point, the Polarstern must be navigated with great care. Its design as an ARC 3-class icebreaker means that it can sail through ice up to 1.20 meters thick at a speed of around four knots (approx. 7.4 kilometers per hour). If the ice cover becomes thicker, however, or if floes pile up to form meter-thick pressure ridges, the only way to navigate through is to search for cracks or other weak spots in the ice. The last resort at the Polarstern's disposal is to ram the ice. It repeatedly backs up, then uses the full 20,000 horsepower of its four engines to charge into the ice and break it up meter by meter.

The ship finally docks in Atka Bay, about 20 kilometers from Neumayer III. There is no quay, but the huge edge of the Ekström Ice Shelf serves as the unloading point for the ship's cargo. "The edge is up to 14 meters high and must have a sharp slope so that the ship can dock directly alongside the ice shelf," explains Heitland, who will be traveling to Antarctica for the third time in 2020. After testing the stability of the ice shelf, the ship's cranes hoist the fuel tanks and containers beyond the ice edge.

Living and working on Neumayer III

The Neumayer III polar research station was built in 2009 and is primarily used for research in meteorology, geophysics and atmospheric chemistry. Other research projects focus on infrasound and marine acoustics.

With a view to future missions to Mars, vegetables are grown in the artificial garden "Eden ISS". In normal years, nine people spend the winter on the station and stay for a maximum of 14 months. For nine of those months, they are cut off from the outside world. This team of Üwis includes the doctor and station manager, four scientists, a cook, an IT specialist, an engineer and an electrician.

During the summer months from mid-November to early March, up to 60 people stay on Neumayer III. The winter team takes a four-month training course to prepare for the extended stay in Antarctica. During the training, they gain specialist knowledge about the sixth continent and their technical disciplines. They are also given fire protection and glacier training and learn how to drive a snow groomer. In case of any medical procedures, Neumayer III has a modern, well-equipped operating room. In their free time, the crew can make use of the station's facilities, including a fitness room, sauna and library.

It takes two to three days to unload the ship and stow the supplies at the Neumayer station. There is no time for any mishaps, as the ship has to set off again right away. It spends a total of 310 days a year on the world's oceans and has already covered over three million kilometers at sea since it was commissioned in 1982. "Loading and unloading the ship is a complex logistical process, with a precisely defined sequence for loading and unloading the containers," says Heitland, a native of Tübingen. Precision is also key when stowing the cargo at the station, he says. "We're in Antarctica, we can't afford to be searching through a chaotic mess."

Getting the supplies from the ship to the Neumayer station is the task of the snow groomers. The vehicles are manufactured by Kässbohrer Geländefahrzeug AG and are known worldwide under the PistenBully® brand. The specialists from Laupheim have been supplying snow groomers to the Alfred Wegener Institute for use in Antarctica since the early 1980s. 20 PistenBully 300 Polar vehicles and one PistenBully 100 are currently in use at Neumayer III. Normally, six vehicles are used to transport all the containers and tanks loaded off the ship to the station using special sleds for 20-foot containers.

The versatile PistenBully 300 Polar was specially configured for use in the Antarctic. So when it comes to unloading the Polarstern, not only is the main frame made of special steel reinforced for heavy hauling work of up to 50 tonnes, the snow groomer also has a special heating system, drift snow covers and height adjustments that enable it to operate in extreme conditions of up to minus 50 degrees Celsius. At the same time, the PistenBully uses a special bio-hydraulic oil to make it environmentally compatible for use in Antarctica.

Without the snow groomers, life at the Neumayer station would surely be more difficult. Not only are they essential for transporting supplies from the ship to the station, they are also used for a variety of everyday tasks, such as clearing, preparing the ground, transporting equipment, even providing a place to sleep at the station. One of their most important functions is to replenish the foundation beneath the station every year to prevent it from sinking into the snow and ice of Antarctica like its predecessors. "Neumayer III stands on hydraulic stilts. Once a year, the stilts are raised up in turn and the holes are filled with ice, which has a similar density to concrete here and is therefore extremely stable," explains 44-year-old Heitland. As a result, the station still remains about six meters above the ice, even after ten years – despite the fact that one to two meters of snow are added every year.

Neumayer III stands on hydraulic stilts. Once a year, the stilts are raised up in turn and the holes are filled with ice, which has a similar density to concrete here and is therefore extremely stable.

Tim Heitland – Physician and Head of the German research station Neumayer III from 2016 to 2018

The Antarctic remains an adventure, but thanks to modern technology, logistics for the sixth continent have become far more reliable and efficient than in the days of Amundsen and Scott. With a plentiful supply of provisions, the Üwis at Neumayer III can be highly confident of returning home in one piece after 14 months. There is even some time for leisure after work at the station, and the crew have a traditional Christmas celebration. Tim Heitland remembers: "We arranged all the tables in the mess room into one long table and laid it with festive decorations. Our chef really went all out and served up a three-course meal with a roast goose as the main course." The Christmas setting was a little different, however: "It was polar day, so the sun shone for 24 hours."

Info

HASSE & WREDE. A specialist in Visco-Dampers and Hydraulic Dampers.

Alongside viscosity torsional vibration dampers for ships, HASSE & WREDE, a Knorr-Bremse subsidiary headquartered in Berlin, primarily develops, produces and markets viscosity torsional vibration dampers for passenger car, commercial vehicle and industrial engine applications. In the marine sector, torsional vibration dampers are used both in harbor tugboats or supertankers and in research vessels such as the Polarstern. They reduce torsional vibrations throughout the drivetrain, prevent crankshaft fractures and thus ensure safe engine performance. A ship like the Polarstern has four propulsion engines, each equipped with a torsional vibration damper. These dampers usually have to be overhauled or replaced every five to ten years.

HASSE & WREDE has manufacturing facilities in Berlin (Germany), Huntington (USA), Dalian (China), Itupeva (Brazil), Naberezhnye Chelny (Russia) and Pune (India). HASSE & WREDE currently employs around 140 people in Berlin, approximately 85 of whom work in production.