Digital Twin: The new multi-physical model can reproduce all the properties of a damper in a virtual simulation environment. Based on a precise analysis of customer requirements, the simulation enables Hasse & Wrede to design the optimum damper for the application.

Hasse & Wrede is the technology and global market leader in the field of viscous torsional vibration dampers (visco dampers). They reduce vibrations on the crankshafts of all kinds of combustion engines, thus ensuring their safe and long-term operation. With the rise of electrification, the proportion of combustion engines in commercial vehicle drives is set to shrink. That's why Hasse & Wrede already has a clear strategy for the future. What does it have to do with twins, the city of Pisa and wind turbines? Managing Director Markus Mali shares insights from the development department, conversations with customers and presents the company's visions.

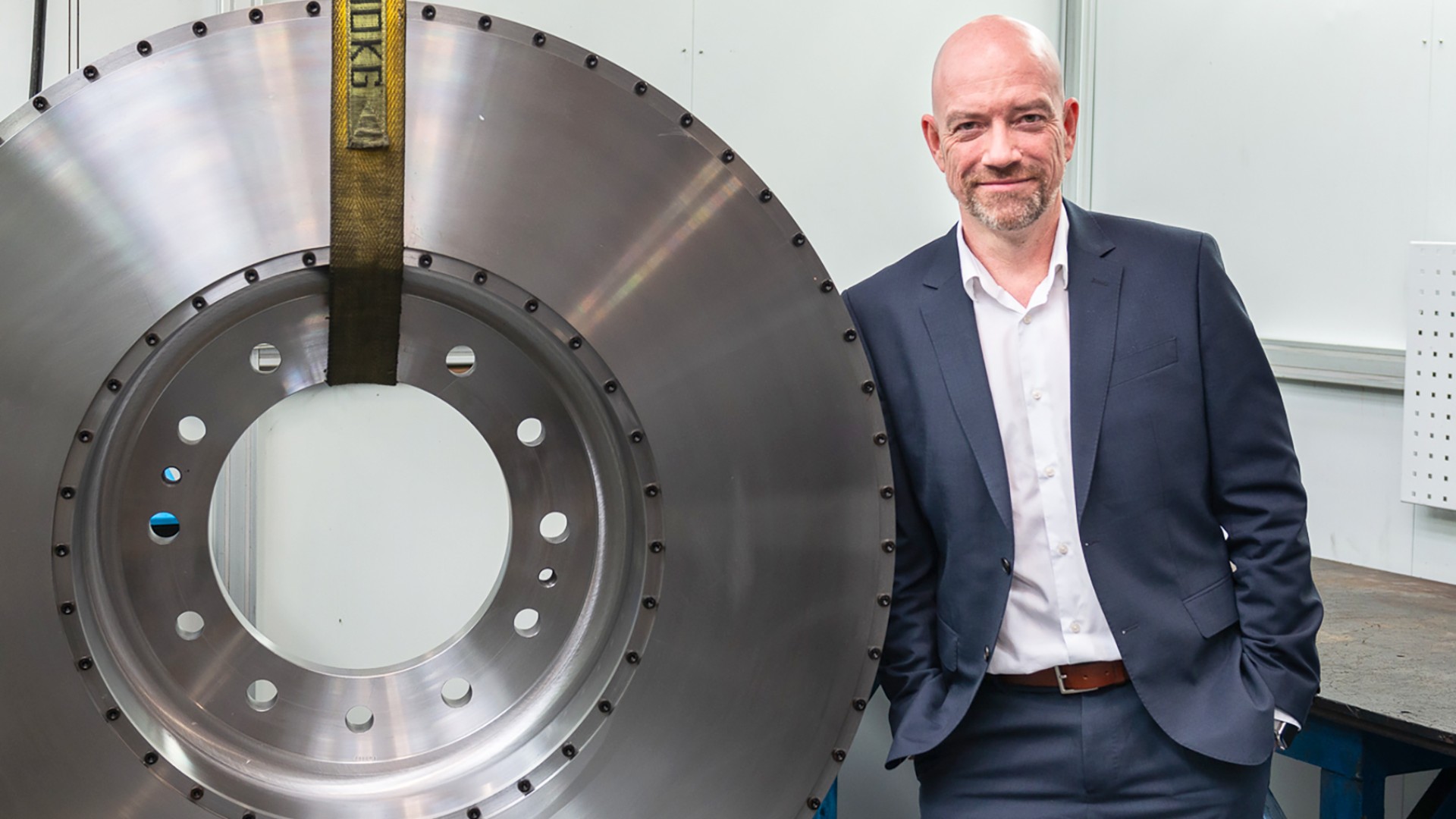

Markus Mali

Markus Mali, Managing Director Hasse & Wrede, dived into the world of torsional vibration dampers as a mechanical engineering student at the turn of the millennium. At that time, he spent two years as a student trainee at Hasse & Wrede and wrote his dissertation at the company. After gaining professional experience at other firms, he returned to Hasse & Wrede in 2007 as Head of Development and took over responsibility for the global damper business in 2016. He has been Managing Director since 2020 and is positioning the company for the future. Cooperation with universities around the world and the continued employment of many students at H&W remains very important to Markus Mali.

How is Hasse & Wrede's product and customer portfolio currently structured?

Markus Mali: Roughly half of our business consists of dampers for on-highway applications, i.e. for engines in commercial vehicles such as trucks and buses and, to a lesser extent, passenger cars. The other half of our business comprises dampers for off-highway and industrial applications. This includes a wide variety of equipment powered by combustion engines that is not used on the road - for example in agriculture, construction, on water or in power generation.

Why would a successful company realign its portfolio?

The torsional vibration damper market segment for on-highway applications is largely saturated and will shrink as e-mobility grows. Electric drives will most likely not require visco dampers. That's why we have defined and adopted a strategy for the future, developed new innovative products and are now strongly pushing our off-highway business. It offers us significant growth potential overall and especially for large applications. These include large reciprocating compressors, wind turbines, generator systems and various marine applications. Our recently developed products are perfectly suited to the off-highway business. This will enable us to significantly expand our market share in this sector and more than compensate for the downward trend in on-highway business. Despite the impacts of e-mobility, we expect significant sales growth for our global business in the medium and long term.

What are torsional vibration dampers?

Torsional vibration dampers are required to reduce the stresses caused by torsional vibrations in drivetrains of engines and compressors to a safe level. The dampers prevent crankshaft breakage or other damage to the drivetrain and thus ensure safe, quiet and long-term operation of the system. Previously used primarily in classic combustion engines, the dampers are set to be used increasingly in engines with alternative fuels, in large compressors and large systems such as wind turbines.

You seem very confident that the strategy will bear fruit.

Our development expertise is key to our success. When it comes to product development, we focus on "first time right". In other words, we can provide customers with a fully functional product from the very first prototype. Another distinguishing feature is our time-to-market - we are very quick to develop a solution, bring it to series production and validate it. Together with a high degree of cost awareness and our global production and development footprint, we have everything it takes to successfully implement our strategy for the future.

Is every product unique? How can you develop efficiently?

It's true that there is no modularity in the sense of one damper being used for multiple different customers and applications. Every customer has their own installation space specifications, their own mounting dimensions and their own requirements. However, what primarily drives customization are the very specific vibration characteristics of the different engine applications. That's why we use the technical specifications provided by the customer to precisely design the components in advance. We achieve this with our simulation model, the Digital Twin. It is an absolutely unique selling point.

Can you explain the Digital Twin in more detail?

With its current capabilities, the Digital Twin is the result of decades of research and development work. It is a multi-physical model that reproduces all the properties of the damper in a powerful virtual simulation environment. With this tool, we can meet the requirements and expectations of our customers to a very high degree. The simulation allows us to precisely analyze the system, consisting of the damper and customer application, and to design the optimum damper for it. Besides the pure damper function, we consider the product service life requirements during development. The most important aspects here are the wear of the silicone oil and the bearing components, as well as the structural strength of the metal components and the welded joints.

And does your development team use this Digital Twin internationally?

Yes, we use the model for all known damper applications in the global on- and off-highway sectors. The work is carried out by a relatively small, highly specialized team. Research and pre-development are performed in Berlin. Series development is undertaken by global teams. We serve customers all over the world with our innovations.

How does the small development team reach its high level of innovation?

We cooperate with industry partners and technical universities on specific topics and problems, from Aachen to Athens, so to speak. We cultivate these relationships and work specifically with partners on small interdisciplinary projects. This may involve the joint development of new calculation models or simulation methods, but it can also apply to the current product portfolio. Topics here include component wear, our silicone oils and developing new components such as special elastomer seals.

Could you outline such a development project?

One recent example is a torsion spring whose structure we developed in close cooperation with a university in Pisa. This type of spring has a highly optimized structure designed for durability, modularity and maximum use of installation space. The torsion spring element gives the damper system additional rigidity and enables us to tune special damper types even more precisely, thereby enhancing performance.

Do these partnerships also feed into your strategy?

Yes, this is where our strategy comes full circle. Because as the degree of application diversification increases, so do customer and market demands on our dampers, which in turn requires us to come up with new technological innovations. We can only maintain this high level of innovation in cooperation with highly specialized partners. They help us to continuously improve in many areas and respond to technical challenges. I am thinking here of areas such as performance, consumption, downsizing, weight optimization, use of installation space and variant diversity.

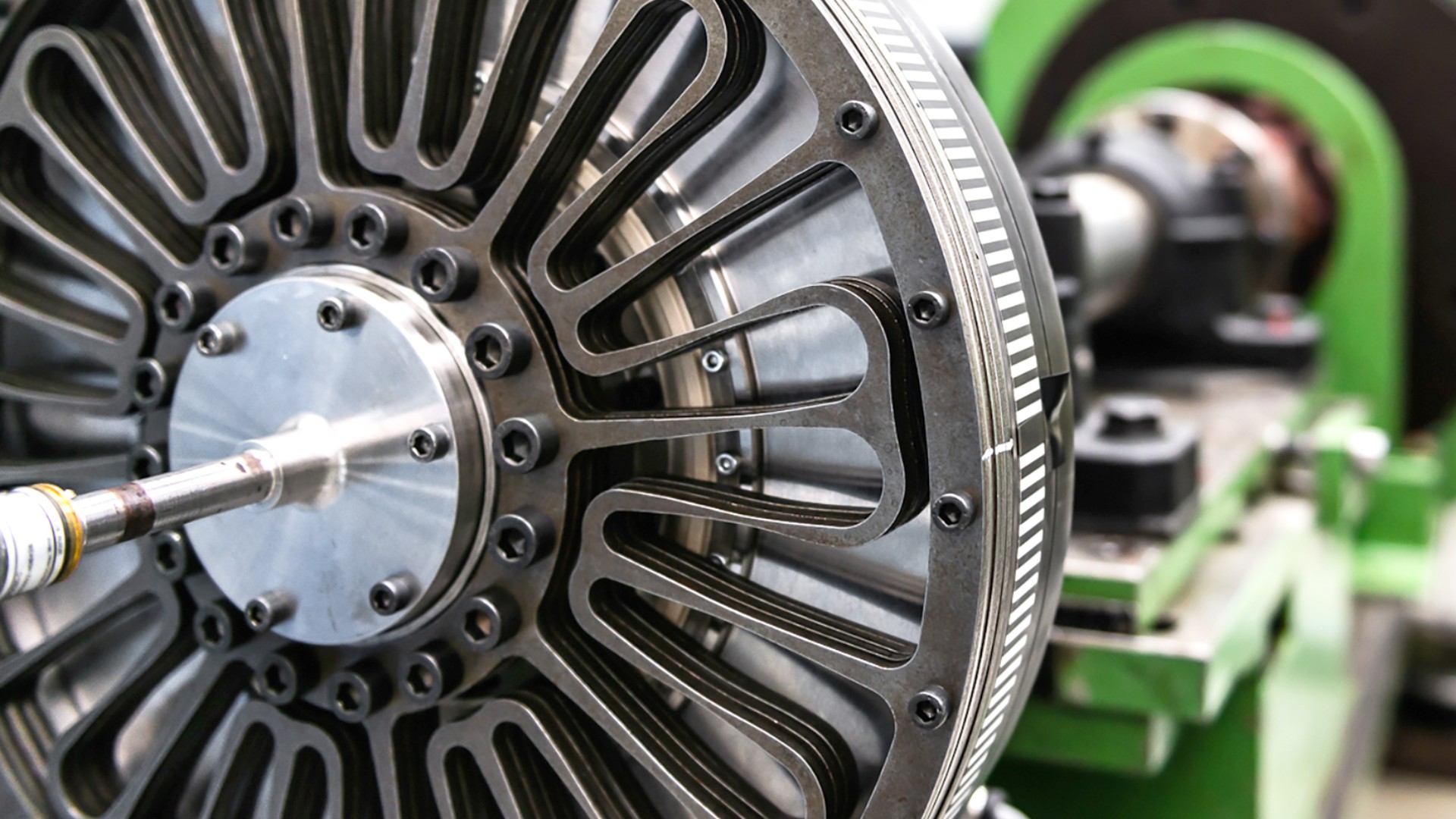

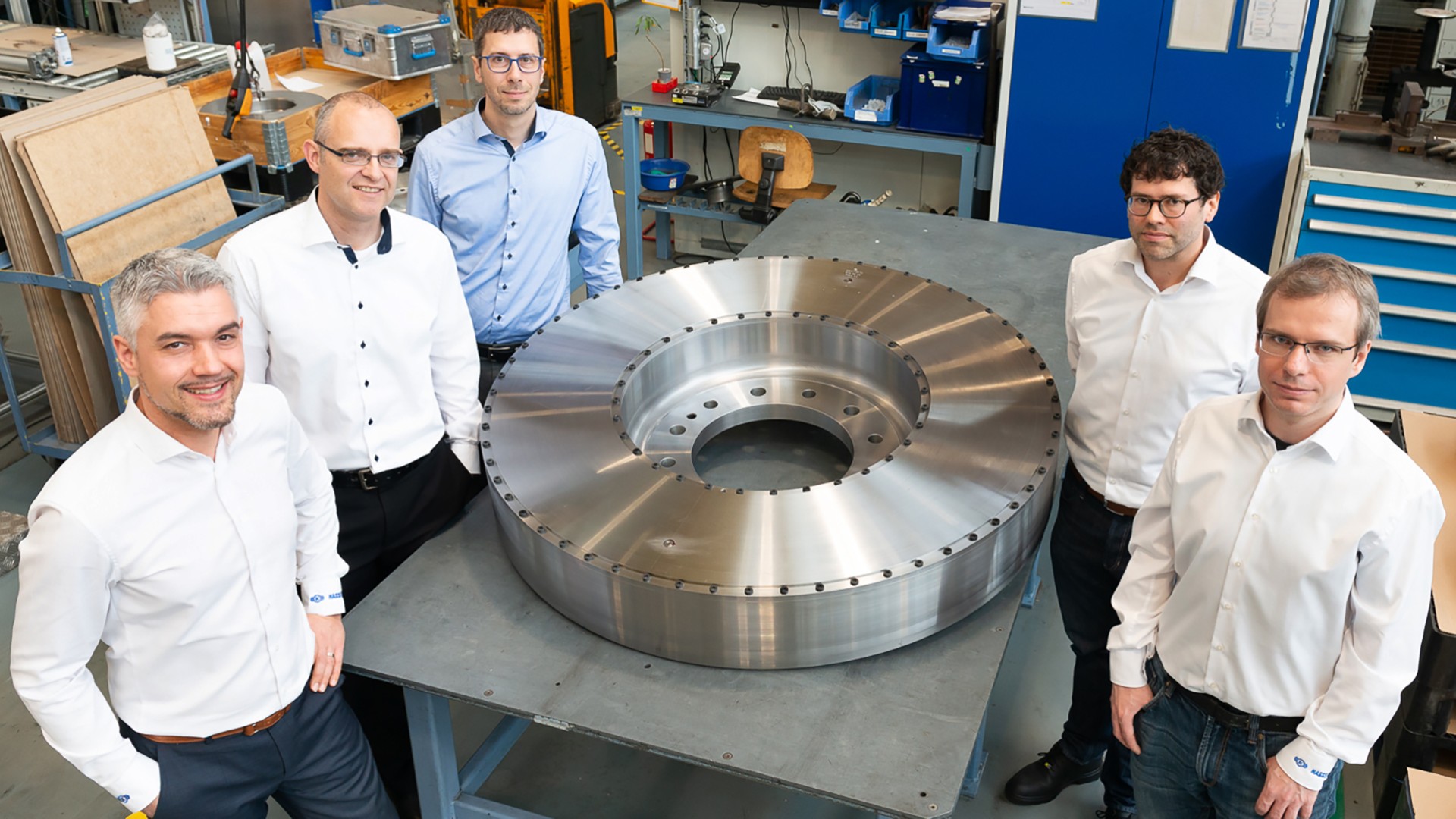

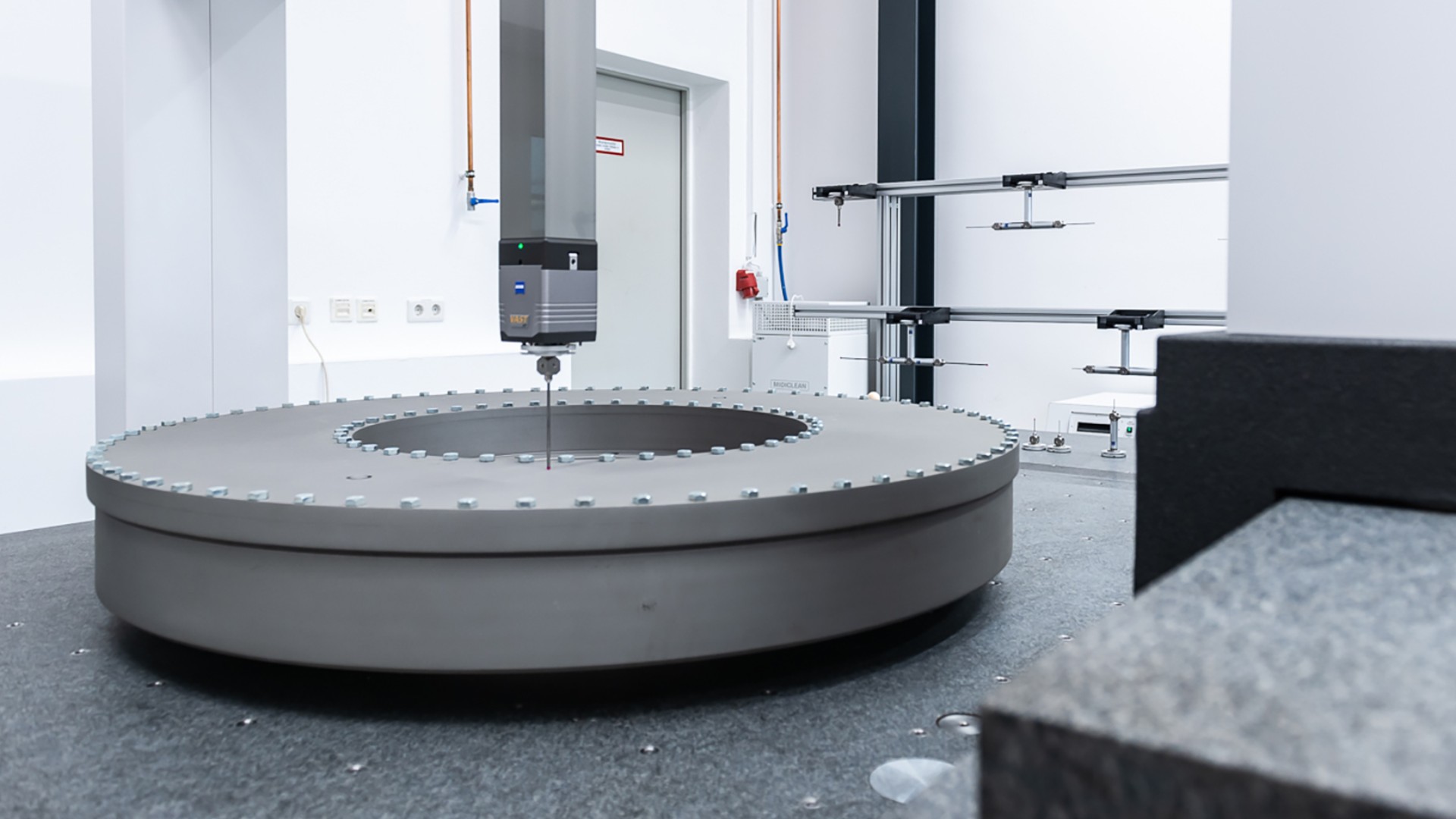

Impressions from Hasse & Wrede production

Does your capacity for innovation also flow into the commercial vehicle business?

To achieve the climate protection goals, CO2 emissions must be reduced. As a result, the market for combustion engines in the truck segment will shrink. Well-founded industry studies predict that the proportion of electrified trucks will rise to over 30% by 2035. At the same time, however, the remaining diesel engines will continue to be optimized in terms of consumption and performance and some will be upgraded for alternative fuels such as hydrogen. Furthermore, diesel engines will continue to play a significant role for much longer in markets such as Latin America, South East Asia and India. So there is still plenty of demand for development and innovation among our commercial vehicle customers, which we will certainly meet.

And which off-highway applications are you targeting?

We are currently positioning ourselves very broadly here. On the one hand, we are looking at the classic large diesel and gas engine applications in the areas of power generation, construction and agricultural machinery, rail transportation and marine systems. Our long-standing customers already include many well-known manufacturers in these industrial segments. We will continue to develop these relationships while at the same time acquiring new large engine manufacturers. Driven by the global pursuit of CO2 neutrality, entirely new market segments are also opening up for us - segments where we were not represented in the past. These include, for example, industrial reciprocating compressor systems, which are required for compressing and transporting gases such as hydrogen. We have already delivered the first damper solutions for a major American compressor manufacturer. These systems have huge dimensions: the required damper has a diameter of 1.30 meters! Then there are wind turbines, which have taken on massive importance thanks to their ability to generate carbon-neutral energy. Particularly in the highest performance classes of wind turbines, torsional vibration dampers are required to reduce noise produced on the generator shaft. We are currently analyzing and evaluating this market to see how we can best serve our customers.

Is your expertise recognized in the new markets?

We have compelling references and can meet customer needs in our future markets. Behind every torsional vibration problem lie similar physical principles. Our expertise is in reducing torsional vibrations by mastering the physics involved. In principle, this works in the same way for a wind turbine as for an internal combustion engine. We have already proven ourselves in many projects in the large engine sector, and we still need to do the same in the wind power segment, for example. I am very confident that we will quickly build up a successful track record.

So your portfolio is equipped for the future?

Yes, absolutely! We are pursuing realistic growth plans with solid business cases. With our expertise in complex applications, we can supply companies in our future markets with tailor-made damper technology. This goes for modern combustion engines that run on alternative fuels as well as for the gas compression and wind energy sectors. I see few risks and many opportunities for us here!

Thank you very much for the fascinating interview.

Hasse & Wrede

Founded in Berlin in 1897, the long-established company Hasse & Wrede is today the technology and global market leader in the field of torsional vibration dampers. Having become part of Knorr-Bremse in 1921, the company now produces viscous torsional vibration dampers for commercial vehicles, passenger cars, ships and industrial applications worldwide. In addition to the corporate, production and development headquarters in Berlin with 180 employees and a development facility in China, the production network includes plants in North and South America and in Asia.