Knorr-Bremse subsidiary Kiepe Electric has developed technologies that enable diesel-powered buses and trains in existing fleets to be converted to hybrid or pure electric drive – thereby delivering the short-term key to major savings in terms of energy and emissions.

The transition to sustainable mobility with a high proportion of electric vehicles is not so much a revolutionary process as an evolutionary one. In concrete terms, that means it will take solutions that enable the modernization of existing vehicles and fleets. One option here is to give used vehicles and components a second lease of life, for example through industrial-scale reconditioning. This ‘remanufacturing’ saves not only precious raw materials but also the energy required to manufacture new products. In both road and rail vehicles, the focus of modernization methods is, of course, on the drive system as the decisive factor in terms of energy efficiency and emissions. Kiepe Electric has developed solutions that allow buses and rail vehicles to be converted short-term from diesel to battery power and from hybrid to pure electric drive. The advantage of these “stepping-stone” technologies is that they are available right now: In Motion Charging (IMC) buses, converted diesel buses and hybrid rail vehicles represent three possible routes to greener transportation for which there is no need to wait.

Good urban climate thanks to clean buses

Many towns and cities are planning to electrify their busiest bus routes in a way that makes both ecological and financial sense. On routes with overhead lines – and there are more than 300 cities worldwide that run trolleybuses – new or converted battery-powered In Motion Charging buses can be operated. Trolleybuses with IMC500 technology developed by Kiepe Electric represent a real option for sustainable mass transit concepts in city centers with no overhead-line infrastructure. These energy-efficient, highly flexible, zero-emission vehicles acquire the battery-power they need for their daily operating range when traveling under overhead lines on the edge of town. The practice of charging batteries on the urban periphery and operating in eco-friendly battery mode downtown represents a sustainable opportunity for the mass transit sector.

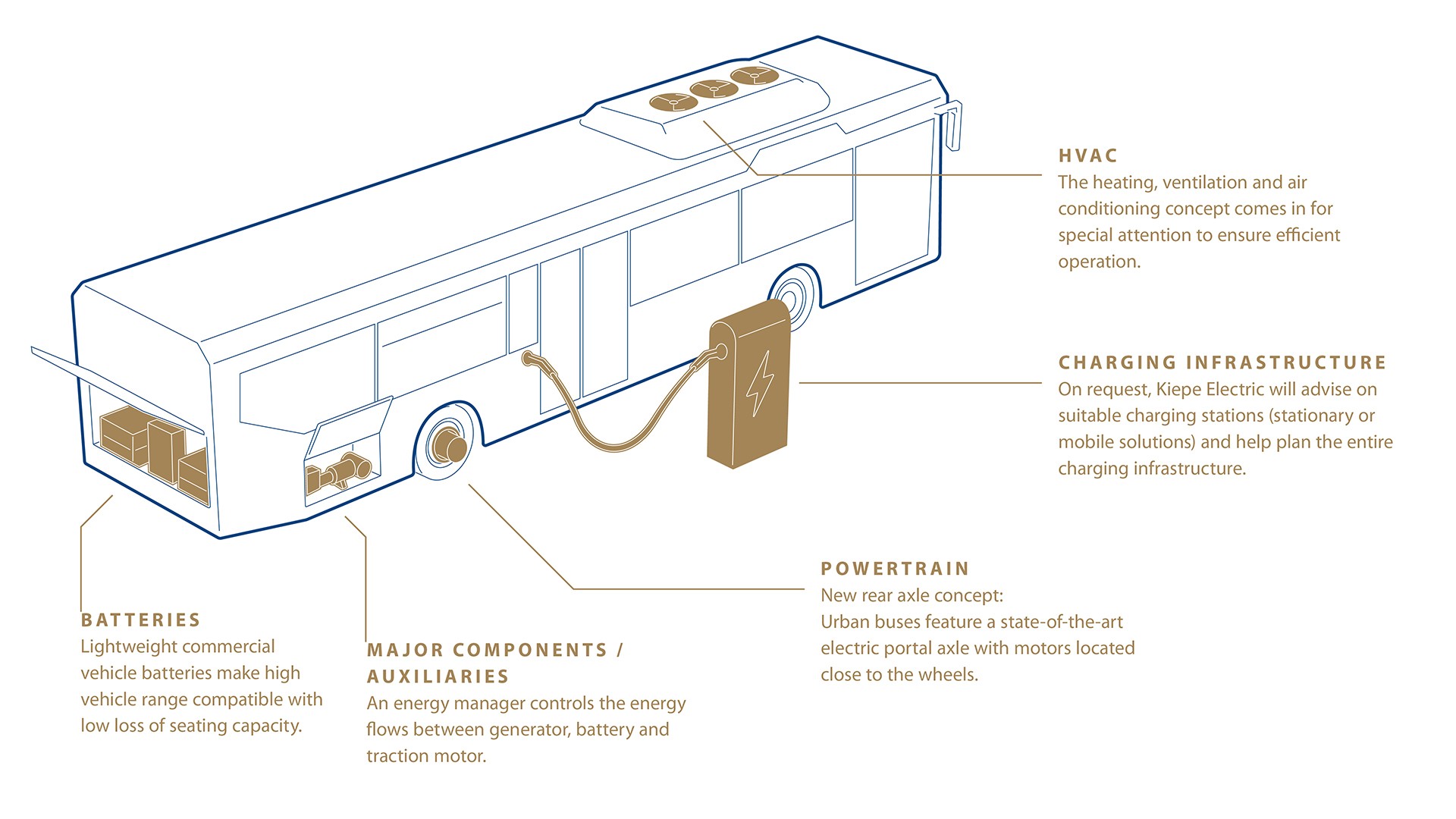

Running on battery power, these buses can operate flexibly on routes with no overhead lines, covering up to 80 kilometers between charges, depending on battery capacity. In this mode, all the energy required for the traction, on-board power and HVAC systems is provided entirely by the traction batteries. Trolleybuses generally have an average service life of between 15 and 20 years, compared to between ten and twelve years for diesel-powered buses. Operating costs are lower too, thanks to reduced maintenance, repair and energy costs. In the German city of Solingen, for example, they have put these advantages to good use: Until 2018, the buses on route 695 with their diesel engines ran for 2.3 kilometers beneath overhead lines without making use of them. Now the city operates buses with zero-emission IMC technology on board.

The idea is to make better use of the existing electric infrastructure in the mass transit sector in order to reduce up-front investments. With this in mind, the experts at Kiepe Electric looked into utilizing the electrical infrastructure of tramways on sections of trolleybus routes. A feasibility study showed that, with small-scale modifications, a tramway substation could also supply a new IMC route. So in the future, electric buses could make use of the power source of their rail-borne counterparts.

Arnhem shows the way

“With our IMC concepts we’re bringing zero-emission mass transit to towns and cities,” says Klaus Kerth, Head of Aftermarket at Kiepe Electric. The city of Arnhem in the Netherlands is already providing an impressive demonstration of what IMC technology can look like at this stage: Early in 2019, two converted electric buses from the Arnhem fleet entered service with state-of-the-art IMC technology from Kiepe Electric. The IMC trolleybuses connect the Oosterbeek and Velp districts and have extended their operating radius to include stretches of route without overhead lines. Arnhem is an early-mover in this respect: As part of the EU’s “E-Bus 2020 IMC” project, the city is transforming its overhead line network into a smart grid. This will use the overhead lines as a power grid, fed from renewables, with charging stations for electric cars and stationary batteries. This means that the IMC infrastructure will be operational 24/7 with a correspondingly high utilization rate.

Cities looking to upgrade their bus fleets can have existing hybrid buses converted to pure electric drive. This involves removing the diesel engine and generator and replacing them with batteries. “Mass transit operators can achieve substantial savings by converting their existing urban buses,” says expert Klaus Kerth.

25% Energy savings for rail vehicles

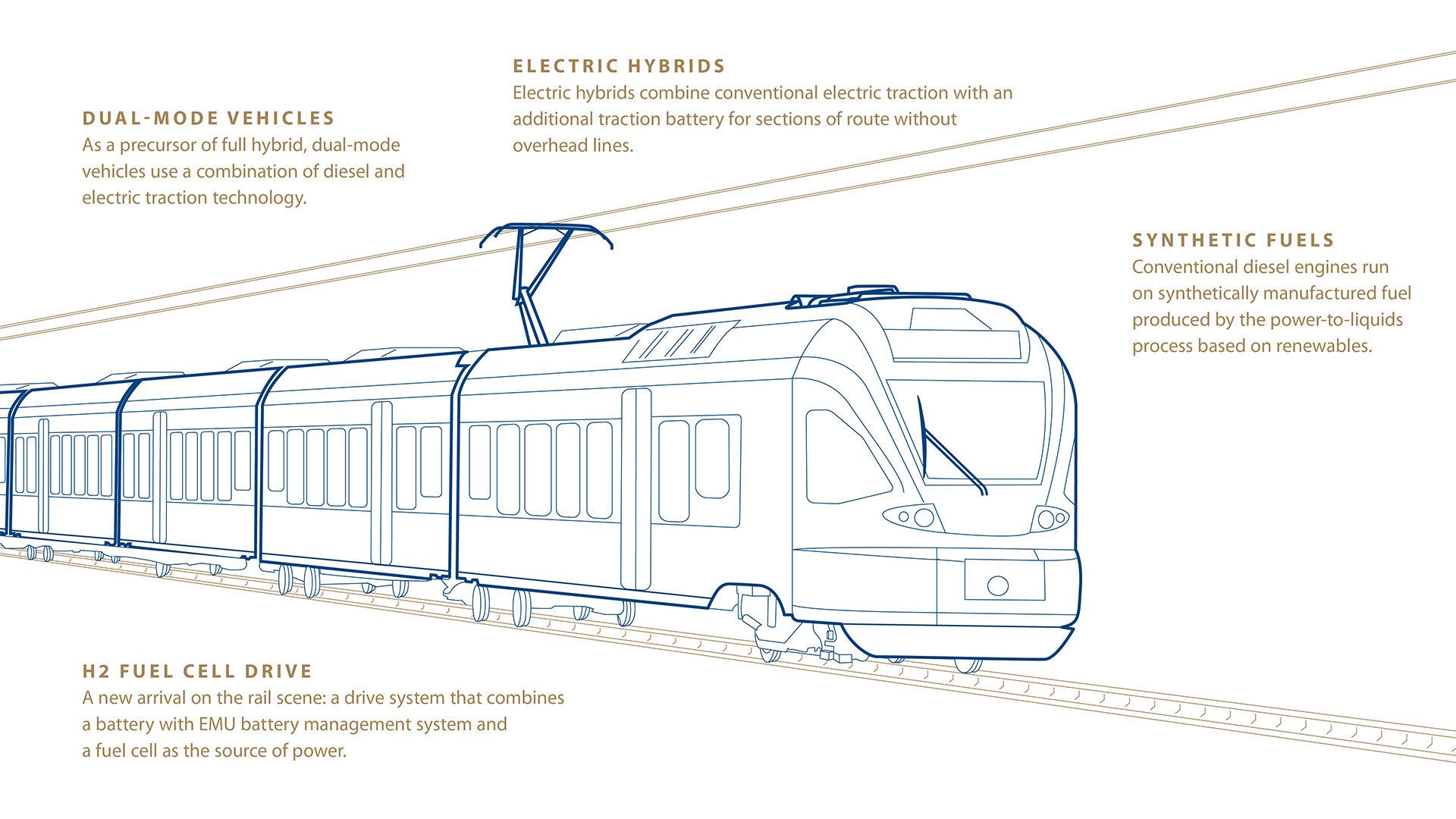

In the rail vehicle sector too, Kiepe Electric has solutions ready and waiting to make transportation more climate-friendly. For the past three years or so, the experts at Kiepe’s Düsseldorf headquarters in Germany have been working on alternative drive systems for diesel multiple units – solutions that are both immediately available and affordable. “We were looking for retrofit solutions for existing vehicles,” says Peter Bunzeck who heads up the Hybrid Train project at Kiepe Electric. “Our stepping-stone technologies are affordable, feasible and available right now. That is the big advantage over buying new vehicles.” And as Dr. Thomas Münch, Head of Equipment Project Planning and Technical Services at Kiepe Electric adds: “In some places it is hard to electrify stretches of track for rail vehicles, and it’s here that stepping-stone technologies currently offer the best solution.” Kiepe Electric has developed a modular concept for mild and full hybrids with a range of modules with which to supplement existing diesel propulsion systems. These include batteries, for example, In Motion Charging (IMC) or brake energy recovery systems. The battery cell technology is the same as in buses; the only difference is in terms of size: While 15-60 kWh is sufficient for an IMC bus, a train will need 120 kWh at the very least, given the mass that has to be moved. Full-hybrid trains with a diesel engine and a transformer for operating in overhead mode can be upgraded with traction batteries with a capacity of 300 kWh and above. And diesel trains with hybrid capability can be upgraded to mild-hybrid units. Before any conversion work can be undertaken, however, it must first be checked which models of train can actually be fitted with batteries or transformers. In this respect, Kiepe sets itself apart from other suppliers by providing integral modular systems expertise, as opposed to just individual electrification solutions. “With our modular building blocks we can offer solutions tailored specifically to the individual customer,” says Project Manager Bunzeck. “Based on this mix, which enables a high proportion of electric propulsion, we can guarantee energy savings that can be of the order of 20 to 25 %, depending on the topology of the route.” Suitable candidates here include current-generation diesel multiple units that are due for a major overhaul in the next few years.

“On some routes that were previously operated using diesel power only, today the trains are either all-electric or use diesel for just 10 to 20 % of the time,” says technology expert Münch. This means that four years after conversion, the vehicles have saved roughly a whole year’s energy. Project Manager Peter Bunzeck sums up the benefits of a sustainable retrofit as follows: “Our modernization measures are designed to pay for themselves, as it were,” he says, “through savings in energy, maintenance and operating costs.”