The vision for Europe’s future mobility network is ambitious: to transport passengers and freight sustainably, rapidly and punctually from door to door. And rail is expected to play a key role. To actualize this vision as quickly as possible, 25 rail industry heavyweights have been working on new technologies since the start of the year, under the EU initiative “Europe’s Rail Joint Undertaking” (ERJU). Of course Knorr-Bremse is involved, playing a major role in several Flagship Areas. In this interview, we discuss the ERJU’s goals, roadmap and successes with Dr. Nicolas Lange, Executive Board member with global responsibility for Rail, and Martin Ertl, Vice President Innovation and Portfolio Management at Knorr-Bremse Rail Vehicle Systems.

Rail industry needs and the associated challenges

Dr. Lange, Mr. Ertl: Europe has been linked together by a rail network for more than 150 years, and rail is currently experiencing a renaissance. But this is posing major challenges to a transportation system that has long been neglected by politicians. What does the rail industry need to become fit for the future?

Nicolas Lange: People have many – often conflicting – ideas on how we can best transport more people and more freight faster and more sustainably. In principle, rail represents the ideal solution. But in many parts of Europe, we have neither the space nor the time to build new railroads, let alone alternative concepts such as the Hyperloop. So the most important thing we can do in the immediate future is make full use of the existing rail network’s transportation capacity.

Martin Ertl: To make this happen, we need to modernize and digitize many different parts of the rail system as a whole, including tracks, signaling technology, trains and communication systems. This is a key requirement. It’s worth noting that all these components have very long service lives, so in principle, this approach would be highly sustainable. But if politicians don’t make upgrading the rail infrastructure a priority, they’ll delay our adoption of crucial innovations.

Nicolas Lange: Freight trains, for instance, are still at the same level of technology as they were 100 years ago. To integrate them into a digitalized rail system, we need solutions based on all-new technologies. But even passenger trains – which are much more advanced – and the rail infrastructure itself need some serious development work.

Martin Ertl: That’s why investment is needed – in signaling technology that enables trains to run more frequently, in automated train services, and in technologies that constantly monitor the rail infrastructure so trackside problems can be sorted out before they result in major construction work and detours. And rail freight services must, of course, become more competitive with road freight services, which still enjoy a cost advantage and deliver door to door.

EU technology initiative: new concepts, new solutions

The EU technology initiative Europe’s Rail Joint Undertaking (ERJU) has been working on precisely these solutions since the start of 2023, with the aim of enabling an efficient, reliable rail system across the whole of Europe. The program is receiving more than one billion euros in funding, and Knorr-Bremse is involved. Who else is taking part, and what exactly is going on?

Martin Ertl: Ten rail operators, 13 vehicle and subsystem manufacturers (including Knorr-Bremse), and two research centers are involved in Europe’s Rail, all from different EU member states.

Nicolas Lange: The key objective of Europe’s Rail is to shift transportation services to rail. To achieve that, we’re aiming to make the whole process of transporting people and freight by rail more eco-friendly, reliable and available. The vision is to improve Europe’s rail network to such an extent that it becomes the number one mode of transportation, more or less “vacuuming” people and freight off the roads – as it already does in Switzerland, for example. But we also want to ensure that rail interacts more intelligently with other modes of transportation. Because whether you’re a passenger or a freight company, if you don’t have easy access to a station, you won’t use rail services. One role model of interoperability is Singapore, which has a highly advanced, integrated mobility system – albeit in a very small city state.

Europe: paving the way to tomorrow’s rail services

So after hearing all this, an obvious question arises: Why is this European-level cooperation only happening now?

Martin Ertl: Railroads have long been part of individual countries’ critical national infrastructure, which is why cross-border collaboration doesn’t have a strong historical tradition. But Europe’s Rail has actually been around for some time. The predecessor program, “Shift to Rail”, was launched back 2012, but focused more on research. Europe’s Rail is all about implementation. The program provides funding for concepts and solutions developed within the agreed framework. The flow of funding is based on the progress of the development work. This incentivizes program participants and encourages them to prioritize what’s really necessary.

Nicolas Lange: There are several reasons why such a results-oriented program has been launched at this particular moment in time. One of the main catalysts is the EU’s Green Deal, whereby EU member states aim to become climate-neutral by 2050 – among other things by reducing the transportation sector’s greenhouse-gas emissions by 90 percent. The transition to an enhanced rail system plays a key role here.

Europe’s Rail: Flagship Areas

What solutions are Europe’s Rail members working on to create a sustainable, future-proof European rail network?

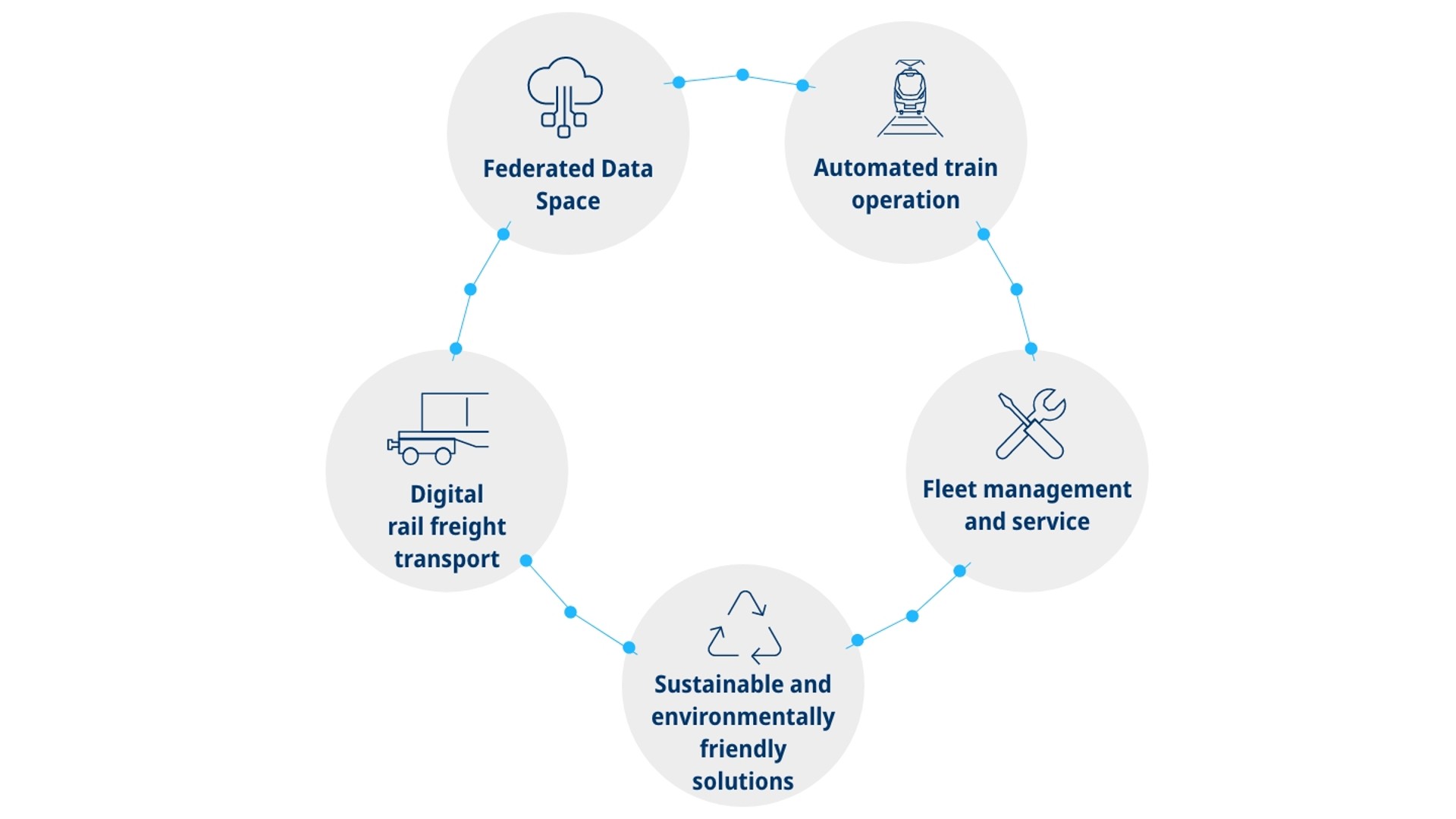

Martin Ertl: The work of Europe’s Rail is divided into six key focus areas, known as Flagship Areas. They’re primarily based on the most important needs of rail operators such as Deutsche Bahn, SNCF and so on. Knorr-Bremse is involved in five Flagship Areas, with nine specific projects and product developments.

What do these five Flagship Areas cover?

Martin Ertl: Area one is about how we use our data to add value for rail operators and rail customers. Area two covers autonomous train operation (ATO). Area three concentrates on maintenance, i.e. reliability and availability. Area four is about finding solutions that will make rail even more eco-friendly. Area five is focused on developing modern, competitive rail freight services. Area six is examining alternative transportation concepts.

DAC: a key technology for European rail freight

How do the various ERJU members work together in these Flagship Areas?

Martin Ertl: The 25 firms involved in the projects agree on the solutions required by the rail sector and define exactly what these solutions should achieve in terms of improving rail transportation. Together, we then do the groundwork, so among other things draw up appropriate technology standards and specifications. After that – but in reality, often in parallel – the individual project participants (like Knorr-Bremse) start to develop specific products. Under our financing agreement with the EU, we promise to deliver the agreed functions in the products we’re developing.

Do Europe’s Rail members work jointly or separately on their developments?

Martin Ertl: That varies from project to project. In the case of the Digital Automatic Coupler (DAC), for instance, several companies are developing their own DACs. But many of the functions are identical, so there’s plenty of overlap. The DAC is one of the key technologies for digitalizing Europe’s rail freight transportation, because it will make it possible to automate the coupling process and equip trains with power lines and data feeds. So even though various manufacturers are working on their own solutions, the magic word is always the same: interoperability.

Nicolas Lange: What this means is that ultimately, all these systems must work seamlessly together – using the same, standardized interface, as it were. This will allow all the rail operators, such as Austrian Federal Railways, Deutsche Bahn or SNCF, to implement their own individual requirements within their respective solutions, but still couple their trains together without experiencing any problems.

Has this development work already produced results?

Martin Ertl: As far as the DAC is concerned, we’re making good, rapid progress, because we’ve been working on it since 2019. The prototypes of our own product, FreightLink, as well as other manufacturers’ products, are already being tested aboard train demonstrators in various parts of Europe. Starting in 2025, we’re expecting to install more of them in freight trains, for operational trials. With respect to the DAC, I think we can safely say that Knorr-Bremse is in a very good position!

Knorr-Bremse: industry pacemaker

Apart from the DAC, is Knorr-Bremse also acting as industry pacemaker in other areas?

Nicolas Lange: We aspire to be the pacemaker in everything we do. This means we often invest more than others. But the ultimate goal is worth it: being able to play up front in a European market for the DAC, for example, that’s worth – if you include installation plus many years of maintenance – between 13 and 15 billion euros.

Martin Ertl: We’re also showcasing our abilities with our electro-mechanical braking system, which will deliver so many benefits in terms of eco-efficiency, weight reduction, connectivity and ease of maintenance. This product will reach further milestones in early 2024. The industry is also showing great interest in other auxiliary functions for modern braking systems, such as Reproducible Braking Distance, which makes braking distances even more precise – at any speed, and in all environmental conditions. This will help rail operators make their day-to-day operations more predictable and stable, paying off in improved punctuality and reliability. What’s more, it represents the next step toward fully autonomous operation.

Nicolas Lange: From a broader perspective, both innovations also contribute to a key objective, which is to make better use of the existing railroad system and infrastructure. Precise, reproducible braking distances should make it possible to reduce the minimum distances between successive trains. This in turn means that more trains will be able to travel on the same stretch of track.

Coopetition at European level

Europe’s Rail is clearly bringing together competitors as partners. How come this combination of cooperation and competition isn’t self-contradictory?

Martin Ertl: The “European ideal” is undoubtedly one of the factors that’s motivated players to come together. While some of us are still competitors, we’re happy to join forces to achieve a major European objective. But even as partners, however, we’re still constrained by anti-trust legislation, and that’s a good thing: We don’t discuss prices, for example. But thanks to the high level of cooperation we all agreed on, we’re all paving the way for market-ready products that share the same functions – products that will ultimately benefit the rail system as a whole.

Nicolas Lange: There’s also undoubtedly a healthy dose of pragmatism behind this cooperation. The challenges facing Europe’s rail industry can only be resolved on a pan-European basis. That’s a legitimate incentive in itself.

The future of rail: the biggest challenges

At this moment in time, autumn 2023, what are the biggest challenges for the Europe’s Rail initiative on the way to building the rail services of the future?

Martin Ertl: The sheer complexity of the projects and their stakeholder structures means the decision-making process is sometimes lengthy and slow. Even so, we aim – and fully intend! – to deliver the promised outcomes on time, at the agreed cost, to the agreed quality standards. And then we’ll need to roll out the products once they’re ready for series production. In the case of the DAC, this means upgrading as many as 500,000 freight cars and 17,000 locomotives. We still have a few hurdles to overcome in Flagship Area one, the “Federated Data Space”. The key issue here is how best to aggregate, analyze and utilize data from all rail operations. The important thing is that all participants – systems suppliers like us, train manufacturers, and rail operators – should share their knowledge of exactly how important this data is from each of their respective viewpoints. That’s the only way to turn this data into knowledge benefiting the rail industry as a whole – so we can avoid disruptions by, for example, using predictive maintenance.

Nicolas Lange: But all these activities depend on one thing above all: money. If you don’t upgrade the rail network, if you don’t finance the DAC, if you don’t fund the digital signaling technology behind the ETCS (European Train Control System) across Europe as a whole, you won’t get a better rail network. And that’s why it’s so important for politicians, for the EU to commit over the long term – political will is what really matters here.

Finally, when you gaze into your crystal ball, what kind of future do you see for passenger and freight transportation in Europe in ten years’ time?

Nicolas Lange: My vision for passenger mobility? A totally integrated system. You travel to the station in a seamless flow of automated vehicles, local mass transit and carsharing services. You sit in reserved seats on the train, and when you get out at the other end, a similar mobility flow takes you to your final destination. And all at attractive prices! In ten years, this should be feasible. But again: We need to want it and be prepared to fund it.

Martin Ertl: In the freight sector, we’ll have completed the migration to the Digital Automatic Coupler and made rail freight substantially more efficient and competitive compared with road freight.

Nicolas Lange: As a result of key innovations and new processes, rail freight should represent at least 30 percent of the freight transportation mix by 2030 – at any rate, that’s what the EU is aiming for. At the moment, the European average is just 18 percent. The example of Austria shows us that 30 percent is possible, so why shouldn’t we achieve this across the continent as a whole?