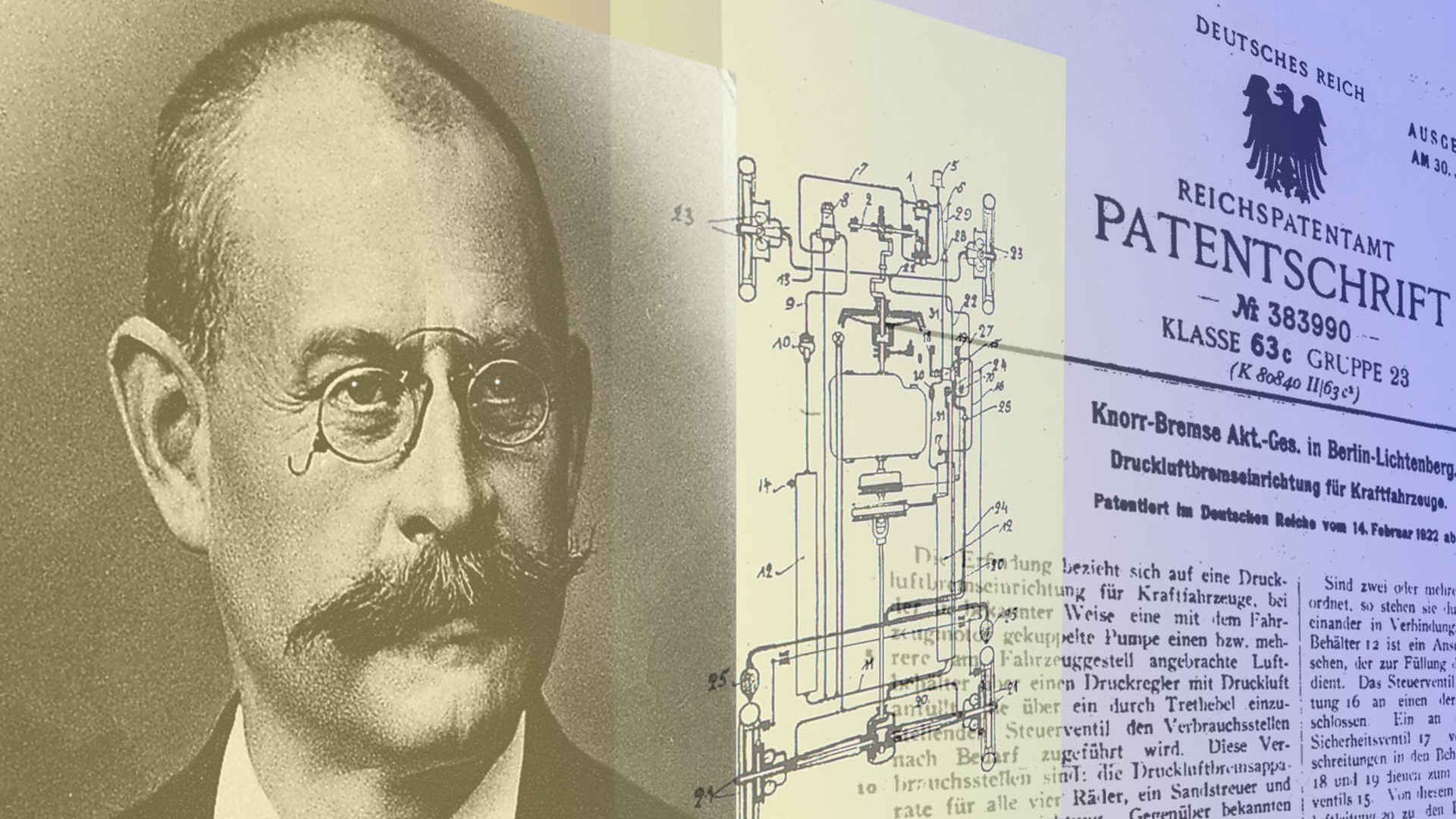

Exactly 100 years ago, on 14 February 1922, patent application number 383 990 filed by Knorr-Bremse Aktiengesellschaft in Berlin-Lichtenberg paved the way for the triumphant success of the compressed air-operated wheel brake for commercial vehicles , which continues to this day. At the time of the filing, the rapid growth in road traffic called for a significantly better brake – to make travel faster and safer.

The breakthrough of the compressed air brake for trucks dates back to a time when a brand-new 5-ton truck tractor from Daimler-Benz would reach daredevil top speeds of 25 km/h on the solid rubber tires that were then standard. Another 2-ton “quick truck” from Daag manages a maximum of 45 km/h on innovative pneumatic tires. Berlin is one of the largest cities in the world in 1922, and one of Europe’s most important industrial centers.

Trucks are on the rise. Better engines, better tires; the one thing that still slows them down is the braking technology. The sheer muscle power of the driver is barely enough to bring the vehicles to a halt via the two rear wheels of the tractor units. Brakemen colleagues ride on the trailers and apply the trailer brakes when called upon; a process that is difficult to synchronize due to ever-rising noise levels in the big city.

Solutions involving rods and levers to transmit the braking forces do not prove effective; they are too prone to error and the braking pressure is not applied evenly enough.

Following the train’s example

At the end of the 19th century, with industrialization gaining momentum and substantially greater forces at work, a key task for railroad engineering was to develop a braking system that acts upon the full length of a freight train. Compressed air had long since been introduced as a medium for power transmission. In 1899, Georg Knorr developed the K1, a control valve that ensured shorter braking distances. This was followed in 1913 by the Kunze-Knorr brake, which enabled the operation of freight trains with a total weight of up to 1,000 tonnes. It also meant that the top speed could rise from 45 km/h to 60 km/h, and later to 90 km/h. All in all, this resulted in a significant increase in transport capacity.

Triumph extends to road transport

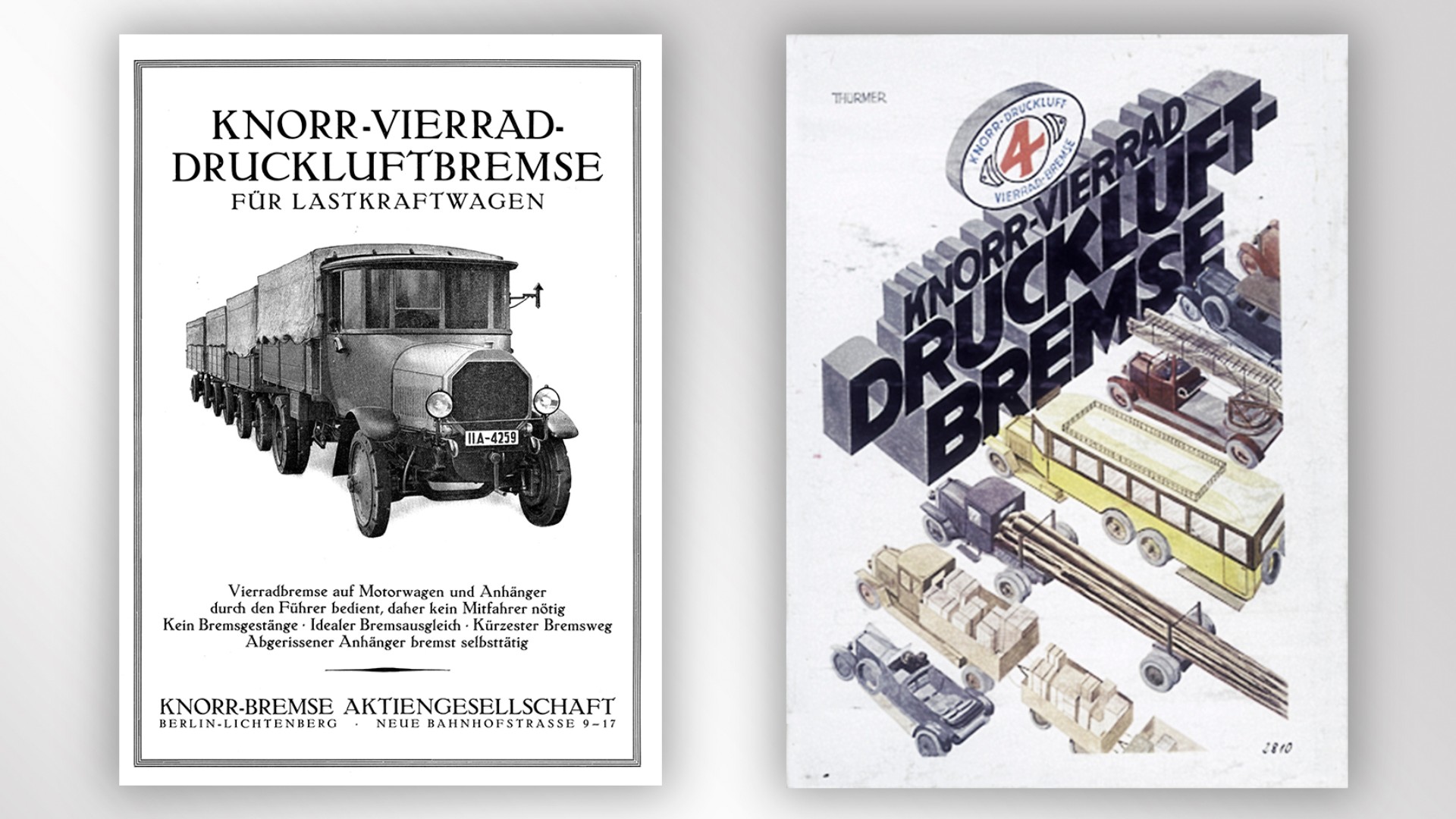

At the end of the 1910s, Knorr-Bremse AG set about adapting “the compressed air brake, which had reached a high level of development in railroad construction, to the demands of motor vehicle traffic. The trials lasted several years. Test drives were undertaken “on the snow- and ice-covered roads of the Ore Mountains, all the way up to Friesland and Holland” to ensure the brake’s effectiveness and operational reliability. The major advantages: Europe’s first compressed air four-wheel brake acts on all wheels of the truck and trailer simultaneously, controlled by operating a single foot pedal. Automatic braking of the trailer in the event of separation from the tractor vehicle also makes the truck-trailer combination safer. Compressed air is generated by a compressor that brings the pressure level in the pipes to 5 bar. Even in the very first advertising brochures, the keywords “low maintenance” and “easy installation” appear alongside “optimum safety” and “maximum effectiveness”.

The new Knorr-Bremse brake really catches the eye in September 1923, when a Horch truck fully fitted with Knorr compressed air brakes on the tractor and trailer unit is unveiled for the first time at the Motor Show in Berlin’s Sportpalast. From this point, the Knorr-Bremse brand is also a household name in road transport. As early as 1930, a trade fair advertisement states: “Please note the Knorr compressed air four-wheel brakes on the vehicles of the companies: Büssing / Daag / Faun / Hansa-Lloyd / Komnik / Krupp / Magirus / MAN / Maybach / NAG / Vomag / Wumag.” In 1933, the magazine “Motor” reported from the Berlin Motor Show: “Knorr compressed air brakes have long since become a byword for the highest level of safety.”

Paving the way for a century of advances in mobility

On 14 February 1922, the compressed air brake for trucks is launched on the market and remains the basis for a multitude of further developments to this day. The drum brake was joined by the disc brake, and actuators were added to convert the air pressure into a linear movement. Compressed air generation itself also became cleaner and more efficient. In the 1990s, electronically controlled systems swept through the commercial vehicle industry. To this day, the compressed air system is at the core of a wide range of additional functions and driving assistance systems that can even steer the vehicle using the braking system if the steering fails.

Braking systems from Knorr-Bremse stand for 100 years of continuous improvements in safety and technology. In the future, too, greater efficiency, sustainability and safety will remain high priorities in the ongoing development of our brakes. The compressed air brake for commercial vehicles will be around long into the future, because whatever drive concept tomorrow’s commercial vehicles adopt, they will always need braking and steering. So we have good reason to celebrate this technology in its glorious longevity: Congratulations on the 100th anniversary!