© Alstom/Design&Styling

Railway technology constructor Alstom is developing one of the world’s most sustainable high-speed trains for French national rail operator SNCF. To this end, operator, constructor and suppliers – including Knorr-Bremse – and their partners are engaging in a new and successful form of collaboration.

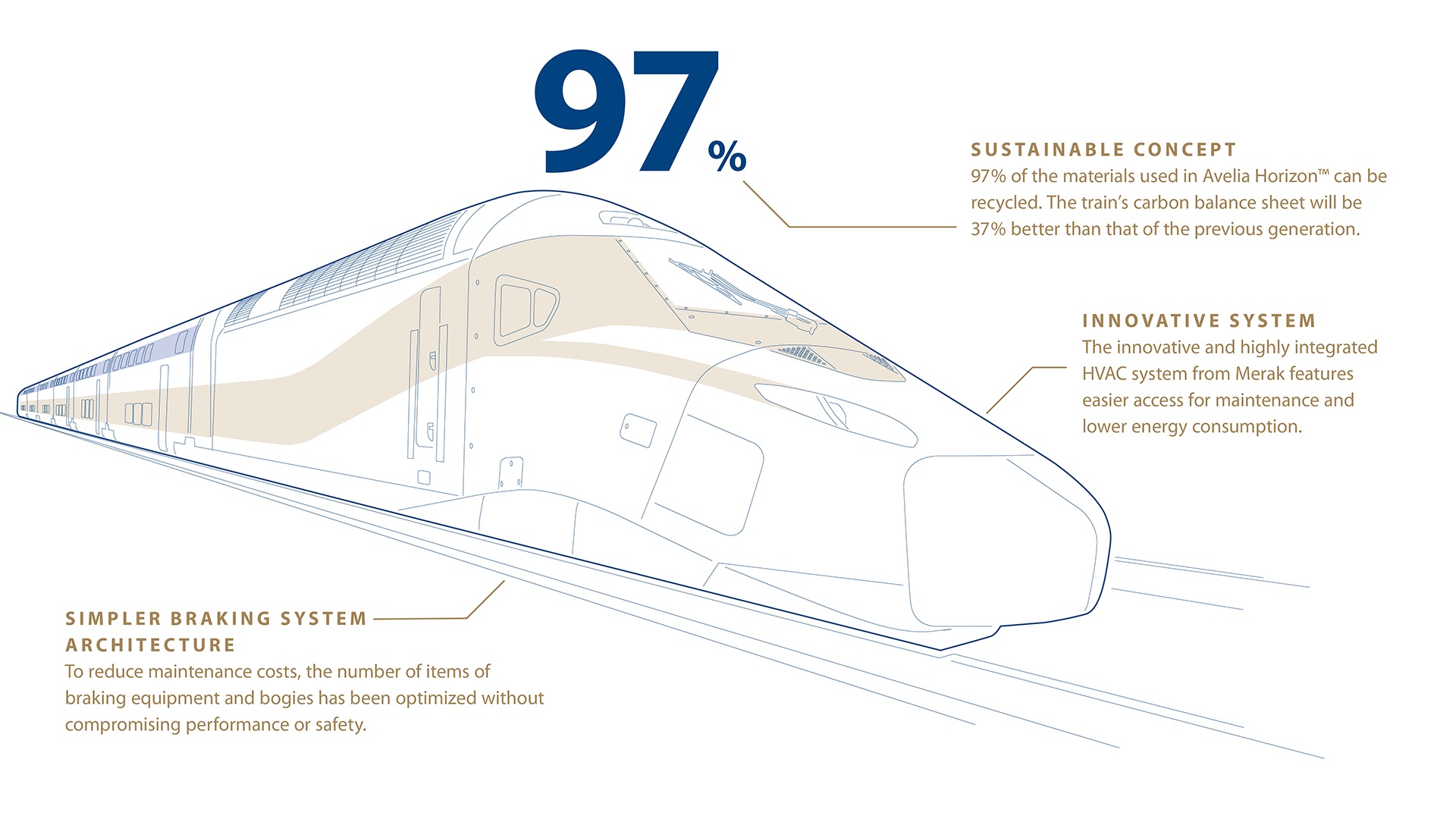

Avelia Horizon™ is due to make its high-speed debut on French tracks in 2023. The train that French national rail operator SNCF calls the TGV of the Future is being developed and built by Alstom in cooperation with numerous partners. These include Knorr-Bremse and its subsidiary brand Merak, who are supplying environmentally friendly, state-of-the-art braking and HVAC systems. End-customer SNCF has set ambitious and trailblazing targets for its new generation of high-speed trains – targets that will lead to an exceptionally innovative high-speed train with impressive performance credentials: an increase (+20 %) in seating capacity from 556 in the second-generation TGV to 740 without compromising on comfort or without increasing the overall length of the train; a drop in the cost of acquisition (-20 %); lower energy consumption (-20 %); and a sharp reduction in maintenance costs (-30 %); all accompanied by greater flexibility, modularity and interoperability.

New Avelia Horizon™ will offer a whole new travel experience and a range of additional on-board services. It will rank also among the most sustainable high-speed trains in the world, which is precisely where the latest technologies from Knorr-Bremse come into play. The trains feature total connectivity, which not only improves what they have to offer in terms of communications and entertainment, but also facilitates the transmission and evaluation of technical data in real time, taking train control and remote diagnostics to a whole new level. What we have here is a masterpiece of innovation “à la française,” as Pascal Désaunay, Technical Director, SNCF Rolling Stock Division and Project Director, TGV2020 puts it – and it began, he says, as an adventure played out in the heads of all concerned.

Engaging in a new form of collaboration, staff from SNCF, Alstom and Knorr-Bremse embarked on an experimental Open Space concept. Instead of everyone working from their own offices as usual, work on Avelia Horizon™ was undertaken collectively. The location was “Plateau”, as the Open Space near the Gare de Montparnasse in Paris was known. Here operator, constructor and suppliers met up as equals and with an unprecedented level of openness.

Samuel Perrin recalls enjoying “the magnificent views over Paris” and found the Open Space “a source of inspiration that made me proud to be part of this project.” The friendly, modern atmosphere at Le Plateau was reminiscent of a startup, complete with coffee machine, meeting corner and bar tables around which people congregated for informal workshops. Perrin was Knorr-Bremse’s central point of contact for Alstom and SNCF for all aspects of the innovative braking system for the new TGV platform, and he was also responsible for coordinating the activities of the technical team tasked with the development work. Where the HVAC system was concerned, Maite Larraya Irigoyen was responsible for communications between Plateau and Merak.

A New Way of Working

Jean-Marc Tessier, Project Manager at Alstom, says that Avelia Horizon™ “brought a change in the way we work, as we shifted to a partnership-like model in which customer, constructor and suppliers saw themselves as a team.” That, of course, asked a great deal of all concerned, as Tessier says: “Above all it called for a readiness to enter into a new form of collaboration, set aside the traditional views of our respective companies and be open for new ideas and technological developments.”

Along with Knorr-Bremse’s undisputed technological expertise, it was this openness for the new form of collaboration which helped ensure that, from the outset in 2017, Knorr-Bremse was invited to move into the Open Space as a project partner. In all, some 800 experts from SNCF, Alstom and suppliers like Knorr-Bremse worked in this innovation lab, among them Maite Larraya Irigoyen, Key Account Manager at Knorr-Bremse subsidiary Merak: “From day one I got on very well with the people from the other companies,” she says. “One completely new side of things for me were the brainstorming sessions in which we didn’t act as customer and supplier but as colleagues on the same team. And the experts from all the various disciplines were on board from the very start of the development process for the new TGV of the Future. For instance there were colleagues specializing in maintenance, and they were able to gain an impression of the entire product life cycle. Another new aspect was being able to respond to the needs and views of the vehicle operator at such an early stage.”

The teamwork was marked not only by in-depth technical expertise but also by a real passion for the product. “All sense of hierarchy was soon forgotten,” says Maite Larraya Irigoyen. “We were all experts, no matter what level we operate at in our respective companies. For me this was the first time I’d been in direct contact with project managers from both the constructor and operator sides. I’d like to see this happen more often in the future, because it’s very conducive to effective collaboration.”

Their joint focus was on the development of a trailblazing new rail vehicle that would set the standards in terms of sustainability, flexibility and comfort, with life cycle costs well below those of the previous generation of TGVs – or as Jean-Marc Tessier puts it: “We have created a train that can meet the needs of many operators.” As he sees it, Alstom will also be supplying “an extremely flexible product that can be rapidly adapted not only in terms of length but of configuration as well, varying the mix of first and second-class coaches.”

According to Tessier, Knorr-Bremse played a decisive part in enabling goals such as flexibility, reduced energy consumption and lower maintenance costs to be met despite the increase in seating capacity. “Knorr-Bremse is supplying the braking and HVAC systems, normally very maintenance-intensive items. Achieving a drastic reduction in maintenance costs was an important step in cutting total life cycle costs.” And with smart energy recovery during braking and a highly efficient HVAC system, electricity consumption will also be down.

Through this successful project, Alstom and Knorr-Bremse are further reinforcing their cross-system collaboration and setting new benchmarks for efficient project deployment and high customer satisfaction. We are proud to be able to contribute products from our portfolio.

Dr. Jürgen Wilder – Member of the Executive Board of Knorr-Bremse AG, responsible for the Rail Vehicle Systems division

Looking to the Future

Developing a new train is “every engineer’s dream,” says Tessier. In this case, the train in question won’t be taking to the rails for a few years yet, but then it will remain in service for 30 years, and until then its performance must be up there with the front runners, particularly where topics like maintenance and energy efficiency are concerned – topics with a bearing on sustainability. So the development of a new generation of trains will always require an eye for the future. As Tessier says: “We must not take our lead from today’s needs; we must anticipate the needs of the future.” Back in 2014, for example, cutting CO2 emissions was already an important goal, given that rail transportation per se stands for sustainability. But today this is also an important advantage in the marketplace, argues Tessier: “If we want to stay ahead of the competition, we need to offer added value compared to other means of transportation. Sustainability and low life-cycle costs are important arguments in this respect.”

In the case of the TGV of the Future, there was further added value for all concerned in the positive way in which it took shape. The formulation of innovation targets at the start of the project and in particular obtaining advance commitments from the project partners to meet these targets, without even knowing exactly how, marked a genuine breakthrough in the development of a new generation of high-speed trains. Samuel Perrin, for one, would like to see the new form of Open Space collaboration used in future projects as well – and if that were to be the case, he’d sign up for the TGV 2050 project right now.