It is the morning of 6 May 2019. There is a palpable air of excitement in the Aachen-Münchner lecture hall of RWTH Aachen University. The final touches are being applied to the stage equipment, the presentation, the food for all the guests. But there is another reason why the students of the Ecurie Aix team are so agitated. In a few hours they will unveil two major results from their many weeks of hard work. This is a premiere – and not only for the parents, friends, lecturers and sponsors present. Many of the Formula Student team members are also about to see the two racing cars they have designed – an electric car and a self-driving vehicle – for the first time "in real life", rather than as computer models on a screen.

The moment of conception

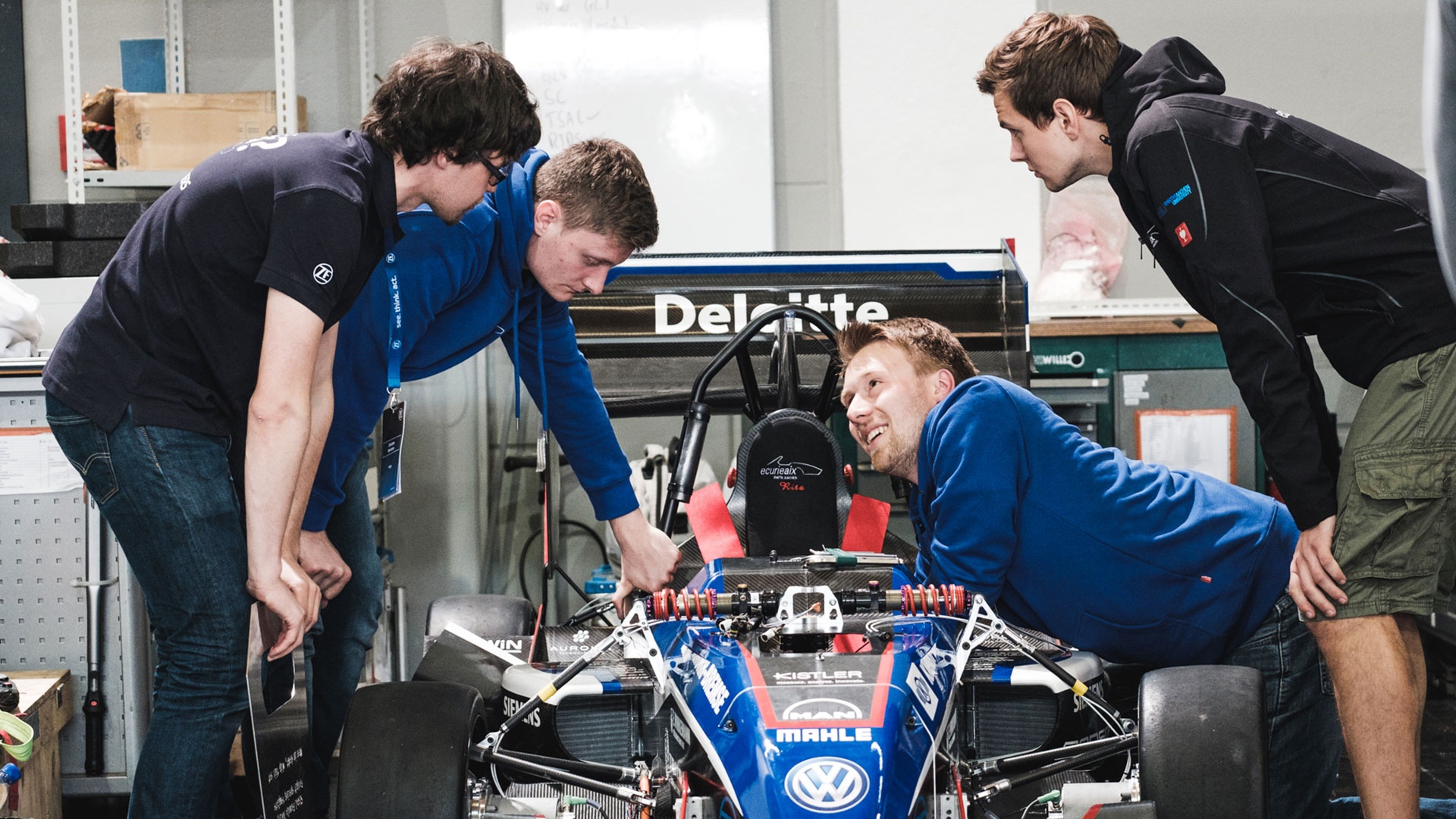

The real moment the two racing cars being unveiled here were conceived, however, came several months ago. Back in September, when last season's cars were completing their final laps around European race tracks, the development team was reassembled for the new season. The students were tasked with building two cars, each posing a completely different mammoth challenge: First, an entirely new vehicle, a “revolutionary car” with an electric drive. Second, they were to convert last year's electric car into a fully self-driving vehicle – a major task and a lengthy innovation process for the sensor and actuator experts (of tomorrow).